Date: 30 April 2013

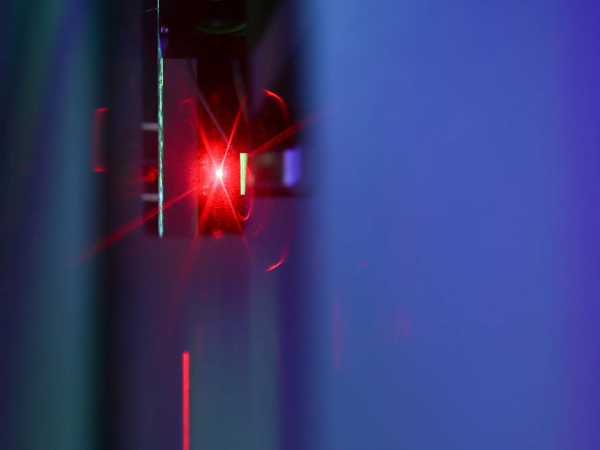

Because these tableware products are transparent, they reflect and refract light, and may act as a lens depending on their shape. Additionally, glass is fragile and must be handled with care throughout an automated system.

One of Turkey's largest manufacturers of glass tableware, S¸is¸ecam Pas¸abahçe (www.sisecam.com), has been producing consumer glass products since 1935 and serving international markets since 1961. Today, the company offers a range of products including glasses, bowls, pitchers, cups, and ashtrays.

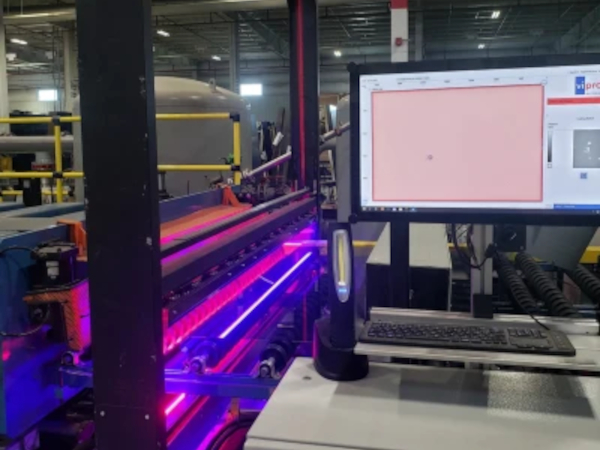

To automate the inspection of these products, S¸is¸ecam Pas¸abahçe selected O2KS, an autonomous inspection unit designed to perform quality control tasks on glass tableware in production environments (see figure). Developed by E3TAM (http://e3tam.com), the system can handle four items per second and detect a variety of flaws including cracks, wavy rims, blisters, and scratches on various product sizes and shapes up to 300 mm in height and 110 mm in diameter.

Using six FireWire cameras, E3TAM's O2KS automated imaging system can be used to inspect cracks, wavy rims, blisters, and scratches on various sizes and shapes of glass tableware.

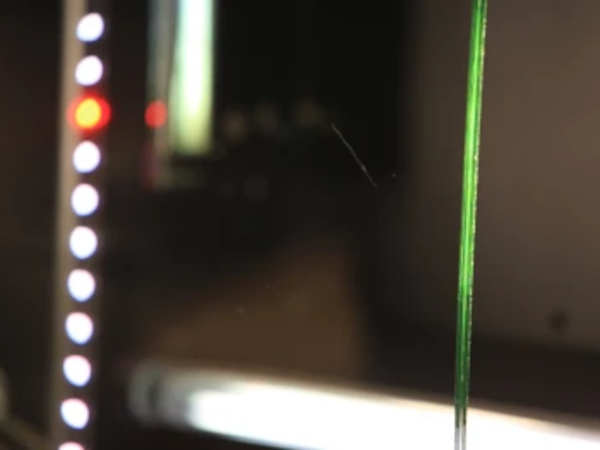

Items enter the inspection station on a conveyor belt and move through four inspection stations. In the first two inspection stages, lateral images of the glass are captured at 4 frames/sec by four 2-Mpixel Guppy PRO F-201B digital FireWire cameras from Allied Vision Technologies (AVT; www.alliedvisiontec.com) situated on the left and right sides of the conveyor. To keep the system as compact as possible, the cameras are oriented vertically above 45° angled mirrors. Fitted with telecentric lenses, each camera captures at least a 90° viewing angle of the object, so the four combined images provide a 360° lateral view of the glass.

To inspect the top and bottom of the glass, two AVT Stingray F-145B 1.4-Mpixel cameras are positioned above and below the conveyor belt. These cameras are used to capture images of the rim and base of the glass and allow the geometry of the glass and any flaws to be analyzed. Both cameras are interfaced to the host computer over an IEEE 1394b FireWire interface.

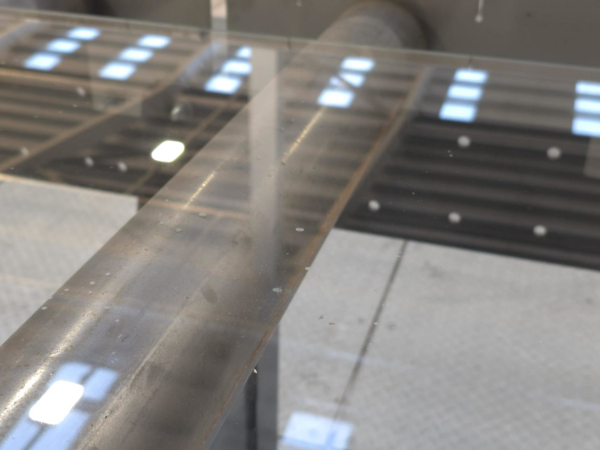

Designing the appropriate lighting was crucial for the accuracy and reliability of the system due to the challenges posed by the physical properties of glass. Because of this, E3TAM developed its own hybrid LED illumination backlight panel. "These contain LEDs placed in different angles such that maximum contrast is achieved while minimizing shadows and reflections from the glass," explains Ali Sami Gözükırmızı, development engineer at E3TAM.

To analyze the captured images, E3TAM used LabVIEW software from National Instruments (www.ni.com) to detect up to 20 different flaws on various shaped products with a precision of 0.6 mm. After leaving the inspection station, the glasses are either conveyed further down the production line or rejected if defects are detected. Using a touchscreen interface, operators can configure the type of glass to be inspected, and, if needed, E3TAM can perform maintenance or customer support remotely.

At present, 20 O2KS glass inspection systems have been installed at S¸is¸ecam Pas¸abahçe's production facilities. Recognizing the success of the system, the Turkish Association of Electronics and Information Industries (TESID) has rewarded E3TAM with an Innovation and Creativity Award.

Add new comment