Date: 4 December 2017

- New adaptable stacked AeroGlass Mirror able to replace any plastic mirror while reducing weight

- Available with EASA Form 1 or Certificate of Conformity (COC)

AviationGlass & Technology (AGT) – a Dutch company specialized in the research, development and production of glass products for the aviation industry – announced that it has unveiled a new AeroGlass Mirror able to replace any existing plastic mirror regardless of its thickness or size while reducing its original weight and disposing airlines of any additional weight penalties.

This also enables airlines to benefit from all the advantages of real, scratch-resistant and shatter proof glass to enhance their cabin design and on-board customer experience possibilities.

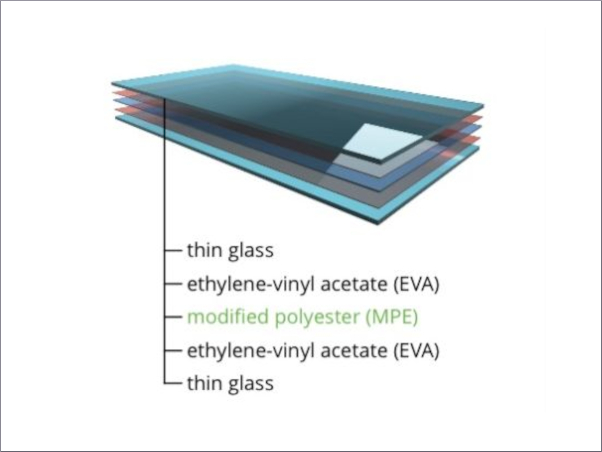

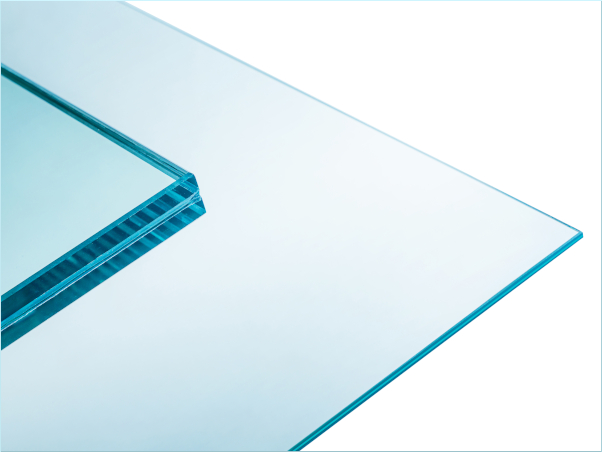

Polycarbonate mirrors in lavatories have thicknesses varying between two to three millimeters while AeroGlass Mirrors are ultra-thin (0.95mm/ 0.037”) and up to 43% lighter than a 3mm plastic alternative. This discrepancy often means that glass mirrors do not fit into the existing mirror assembly space in a lavatory.

To overcome this retrofit challenge, AviationGlass has developed a new stacked version of its AeroGlass Mirror. The ultra-light AeroGlass Mirror is fixed to a layer of foam equaling the exact thickness of the original plastic mirror and delivered using the same mounting system making it easy and fast to install.

Additionally, unlike the jagged, unattractive edges of polycarbonate mirrors, AeroGlass Mirror rims are beautifully finished and smooth removing the need for aluminum casing.

Discounting the weight savings gained from the actual mirrors themselves, the elimination of aluminum trim alone can bring about savings of up to four kilos per Boeing 777 shipset.

AeroGlass Mirrors can be manufactured to produce a lighter, perfect replica of the original plastic mirror including recessed edges, finishing trims as well as integrated signs and light strips.

As with other AeroGlass products, the stacked mirror has passed the impact, burn and heat release tests and can be delivered with an EASA Form 1 or Certificate of Conformity (COC).

John Rietveldt, AGT’s CEO says, “Our new ultra-light, stacked AeroGlass Mirror enables airlines to effortlessly upgrade from plastic to beautiful, durable glass while also helping them reduce weight penalties. Thanks to the easy installation technique, scratched plastic mirrors and unsightly trims can be replaced with smooth glass edges and crystal-clear reflections in a matter of minutes. Decorative elements and lighting specifications can be replicated or tailor-made on demand meaning that each AeroGlass Mirror is a perfect fit!”

600450

600450

Add new comment