Date: 22 June 2018

“Optimising temperatures in glass melt tanks is an essential part of maintaining high-quality glass production and extending the campaign life of the furnace. Infrared temperature measurement can help to improve efficiency and optimise quality within glass production, and the award-winning, best-in-class Near Infrared Borescope (NIR-B) is simply the best instrument for the job. We look forward to demonstrating this latest technology to delegates at the European Society of Glass conference,” explains Philippe Kerbois, Regional Sales Manager - Glass at AMETEK Land.

“Within the glass-melt furnace, there are a variety of temperature measurements that can be taken in different locations. It is important to be able to trend temperature measurements throughout the furnace, such as the crown and port arch areas. The temperature of the melt line and the batch transit time need to be recorded and used for comparison, along with temperature “visualizations” of cold spots in the refractory wall, which can be indicative of air leaks typically caused by structural issues.”

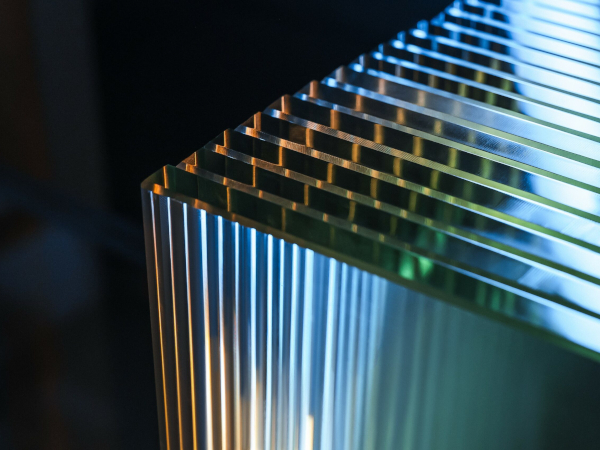

Temperature measurement at critical locations in the production process is essential in glass manufacture and processing. AMETEK Land’s NIR-B Glass is a short wavelength, radiometric, infrared borescope imaging camera that is designed to produce high-definition (656 x 494 pixel) thermal images with over 324,000 accurate temperature measurement points in the field of view.

The camera measures temperatures in the range of 1000° to 1800°C (1832° to 3272°F) and is suitable for float glass, container glass, borosilicate glass and fibre glass melt furnaces.

“The recent advancements in measurement technology that we see in products like the NIR-B are helping plants to make significant improvements in the melt tank process, both in terms of quality of output and a reduction of costs. The addition of thermal-imaging capabilities enables operators to maintain a crystal clear visual of the glass melt tank, as well as take temperature measurements at any point in the process and in any location within the tank. This is invaluable data for any modern glass plant,” adds Kerbois.

Alongside the NIR-B, AMETEK Land manufactures a range of temperature measurement instruments, specifically designed for the glass industry.

• Model FG, a simple fibre-optic non-contact thermometer, monitors glass or refractory temperatures in the forehearth, and in the regenerator, tank and refiner.

• Cyclops L family of high-quality, portable non-contact thermometers provide precision spot temperature measurement with unmatched accuracy and reliability.

• LSP-HD infrared linescanner detects small temperature differences across the width of the glass product, providing optimum product quality through improved process control.

• Lancom 4 portable combustion and stack emissions gas analyser, offers the best accuracy available from a portable gas analyser, achieved by using an advanced sample conditioning system.

For more information on NIR-B Glass and its ability to measure temperature profiles inside furnaces, visit NIR-B Glass - Melt Tank

600450

600450

Add new comment