Date: 30 July 2010

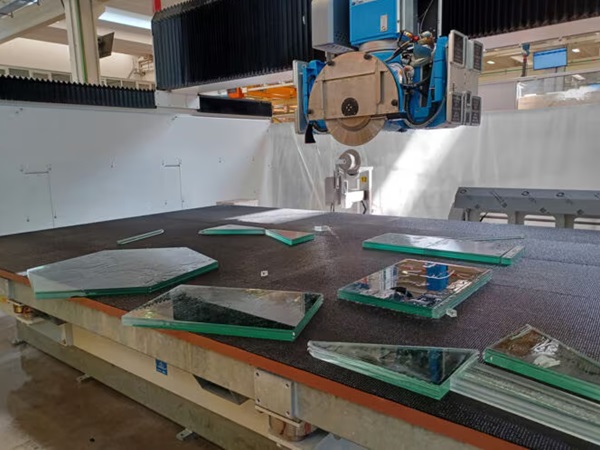

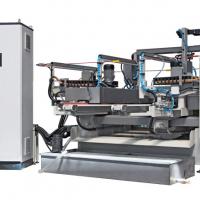

ALCOR-100 operates as a CNC working center with 6 controlled axis.The glass is manually positioned against the reference centering bars, controlled by two axis, it is then blocked and worked by drill bits or routers or wheels depending on the type of required work.Holes from bottom and top, notches, pin and screw inserts Adjustable reference bars on both X and Y axisVery easy to program by CAD-CAM complete with parametric programs Touch screen Fast tool change Technical data:Glass thickness: 2 - 30 mm Hole diameter: 80 mm max.Routing X axis: 200 mm maxRouting Y axis: 200 mm maxUpper spindle speed: 12000 rpm max; automatic adjustmentLower spindle speed: 4000 rpm max; automatic adjustmentUseful range: 1000 mmWorking table height: 1050 mmBearing table: 4000 x 1750 mmTotal power: 14 KW

CNC drilling and routing machine type ALCOR 100 with one double head to perform holes, routings, notches, pin and screw inserts.

ALCOR-100 operates as a CNC working center with 6 controlled axis.

The glass is manually positioned against the reference centering bars, controlled by two axis, it is then blocked and worked by drill bits or routers or wheels depending on the type of required work.

Holes from bottom and top, notches, pin and screw inserts

Adjustable reference bars on both X and Y axis

Very easy to program by CAD-CAM complete with parametric programs

Touch screen

Fast tool change

Technical data:

Glass thickness: 2 - 30 mm

Hole diameter: 80 mm max.

Routing X axis: 200 mm max

Routing Y axis: 200 mm max

Upper spindle speed: 12000 rpm max; automatic adjustment

Lower spindle speed: 4000 rpm max; automatic adjustment

Useful range: 1000 mm

Working table height: 1050 mm

Bearing table: 4000 x 1750 mm

Total power: 14 KW

.jpg)

Add new comment