Others also read

| In this ninth episode of #AskGlaston flat tempering series, we explore how to optimize energy efficiency in the case of short loadings.

| In this eighth episode, we delve into optimizing energy efficiency in Low-E production.

| In the seventh episode of the #AskGlaston flat tempering series, the focus is on the Tempering Autopilot.

| In this sixth episode of #AskGlaston flat tempering series, we explore how to avoid loading delays in tempering.

| Mikko Rantala on Glastory: Glass tempering is an energy-hungry process, and not just because of the heat.

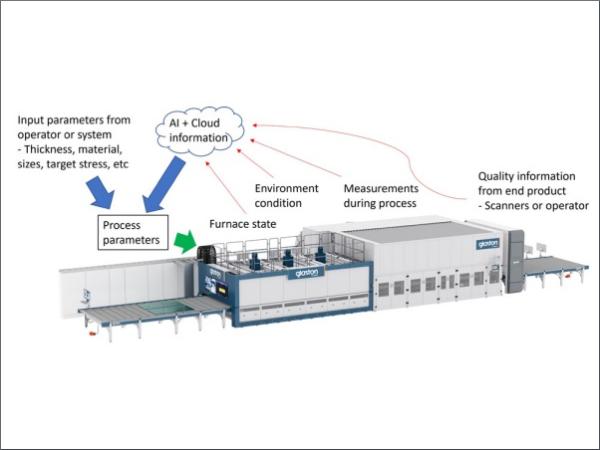

| As labor shortages and efficiency demands grow, automation is transforming glass tempering—starting with AI-driven batch building that boosts productivity, cuts energy use, and maximizes furnace performance.

| This study examines prestressed glass specimens that are 0.5mm, 1.1mm, and 2.1mm thick in comparison to glass of the same thicknesses that have not been enhanced by the novel stiffening method.

| Modern tempering technologies offer impressive energy efficiencies for glass processors. But, have you ever come across energy-saving claims that seem too good to be true?

| Optical stress measurement in tempered glass has its challenges. Stresses can be measured optically based on the optical anisotropy behavior of the glass.

| What glass processes gain the most from automation? In this blog, we’ll focus on some of the particularly promising application areas.

| The latest Glastory blog gives insights on the experiences of the tempering process Autopilot users.

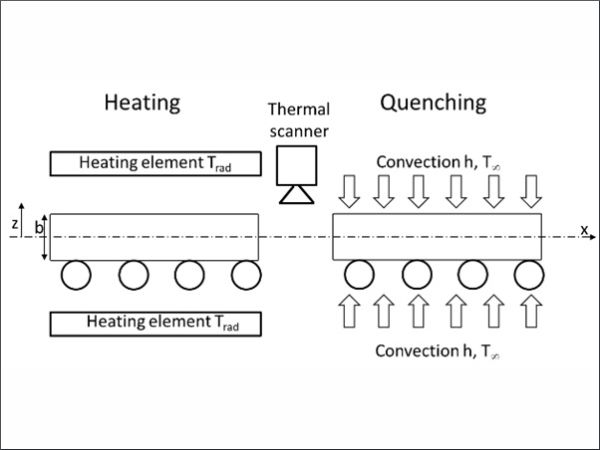

| Glass is most often heat treated before using it as a structural material. In this context, thermal tempering is the most effective and efficient method to enhance the load bearing capacity and strength of glass.

| Glass tempering is a process that can be made in many ways to get tempered glass that meets the standards. The selected way is usually chosen by the operator and is almost always based on experience instead of science.

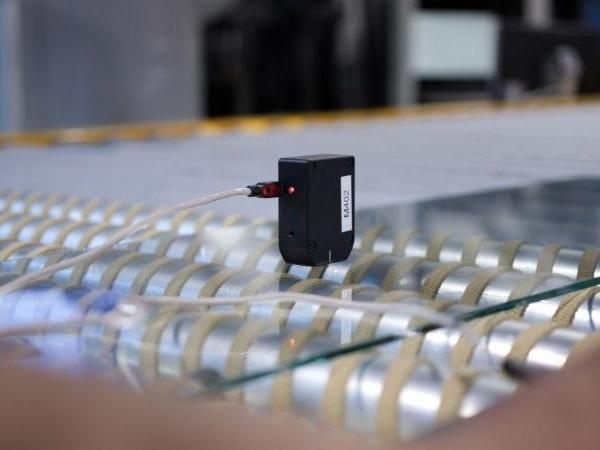

| A way to determine the condition and functionality of a glass furnace is to measure the glass temperature as it exits the furnace.

| In the latest Glastory blog post, Antti Aronen analyzes the transformative potential of automated glass tempering.

| Read the latest Glastory blog by Taneli Ylinen.

| In this third episode of the #AskGlaston flat tempering series, Taneli Ylinen deals with the commonly asked question of how to handle the issues with mixed production.

| The results of the classification of hail resistance classes for different materials for greenhouse enclosures are presented in this paper.

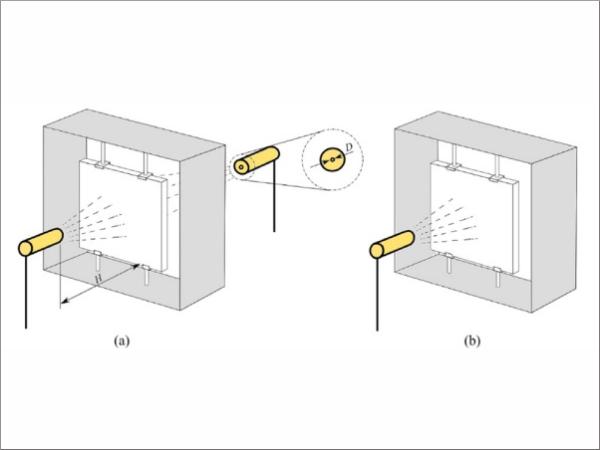

| In this paper, we present the development of an intrinsic parameter σQM characterizing the sensitivity of a coating (or configuration) to the quench marks.

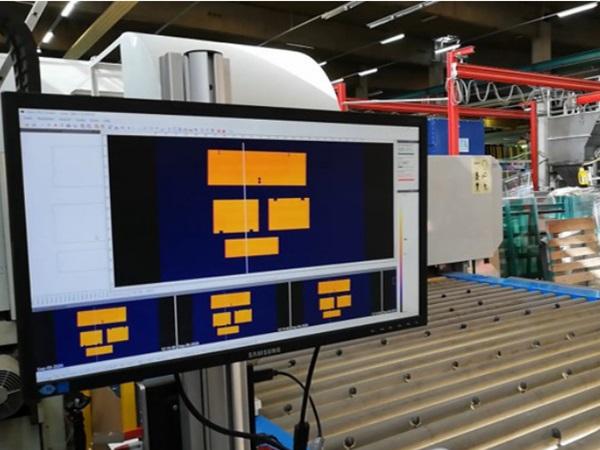

| In the second episode of #AskGlaston Flat Tempering Series, we will talk about the new solution to estimate the stress level in glass – online.

| This first episode is devoted to the white haze phenomenon – one of the most asked about issues in the history of #AskGlaston.

| This latest Glastory blog by Miika Äppelqvist is dealing with the areas of the tempering process that can be improved to make operations more efficient.

| Industry demand for impeccable glass quality has increased notably over the last years. Customer expectations run high, forcing glass processors to strive for ever-stricter quality control and ensure minimal rejection rates for finished products.

| The most common quality issues that arise in tempered glass are roller waves, glass distortion, bad anisotropy and white haze. In this post, we want to focus on white haze and ways to control it.

| In 2015, the bold concept of a curvy tower at 252 East 57th Street, New York, was presented to an audience at the Glass Performance Days conference. At that time, building construction was just beginning, and no one was certain such a novel idea could be realized.