First presented at GPD 2019

Due to design aspects, the transparent adhesives are of particular interest. This article – based on a concluded PhD-theses – focuses on the group of two-component epoxy adhesive. These group of adhesives have hardly been taken into account in the glass technology sector up to now.

Overall, eight epoxy resin adhesives were shortlisted, and thoroughly characterized. The executed investigations are divided into the recherche of suitable epoxy resin adhesives, the characterization of the adhesives, as well the analysis of the adhesive joint. Within the investigation program, great emphasis was placed on a balanced weighting of different criteria. This article provides an overview about the extensive studies to the characteristics and to the behaviour of transparent epoxy resins. [1]

1 Introduction

Transparent adhesive systems that are used in glass constructions and in facades have to fulfill special demands on the durability of their optical quality. Until now, transparent epoxy resin adhesives have received little attention in structural glass construction. Apparent advantages over alternative solutions are the physical properties, the comparatively simple dosage, the adhesive curing without considerable technical effort and, last but not least, the adhesive costs.

The results presented in the following are part of a research project at the Institute of Building Construction dedicated to these adhesives. The paper is divided into the presentation of the adhesives and substrates, the description of the analytical and experimental methods, as well as the presentation and discussion of an excerpt of the results.

2 Materials

Epoxy resin adhesives

The epoxy resin adhesives investigated are twocomponent polyaddition adhesives. An epoxy adhesive is a copolymer formed of an epoxy “resin“ and a “hardener“. The components are homogeneously mixed during dosing in a fixed mixing ratio. In the process of mixture, the chemical reaction and thus the adhesive curing begins. The curing usually takes place at room temperature, whereby a moderate temperature increase accelerates the curing reaction, as well sometimes improves the adhesive properties.

The chemical formulation of the resin component usually contains monomeric or oligomeric epoxies, each of which has two or more reactive epoxy groups (oxiranes). In this case the most common resin is bisphenol-A-diglycidylether (DGEBA). The hardener component contains one or more multifunctional substances such as amines or thiols. Further components of the formulation can be fillers, reactive diluents, crosslinkers or catalysts. [2, 3]

The assortment of adhesives is limited to eight transparent, high-strength and high-modulus epoxy resins. According to manufacturers, all adhesives are suitable for metal or glass substrates, and provide sufficient adhesion on these materials. The selected adhesives come from the three manufacturers Huntsman Advanced Materials, Henkel and 3M. The adhesives are readily available and have been available in largely unchanged chemical compositions for many years. This long-term availability is of particular importance with regard to the use of the results.

The adhesives were processed under normal climatic conditions and then cured at a moderate temperature increase. The temperature increase serves for accelerated curing and should increase the reaction rate and the degree of cross-linking. The selected curing conditions are based on the manufacturer’s recommendations and were evaluated by further own studies.

Glass

The metal cylinders are adhesively bonded on the front side to small-format (see section 3), square glass panes for the investigation of the glass-to-metal connection. Due to the strength of the adhesive joint, the use of thermally toughened soda lime silicate glass is necessary. The glass samples have a nominal thickness of 8 mm (comparative studies) or 15 mm (optimisation studies).

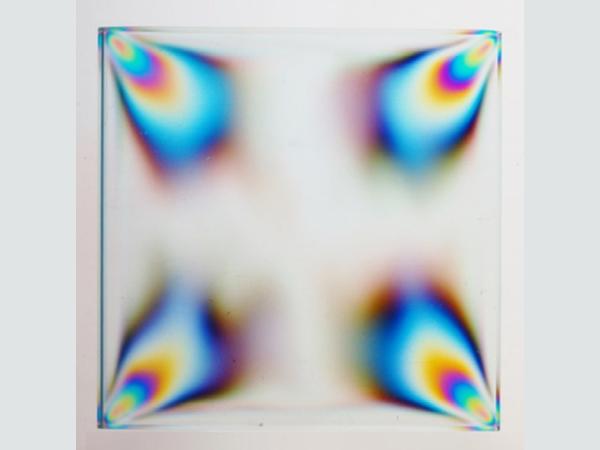

The thermal toughening of the glass samples was carried out in a small tempering furnace. The glass samples have unfavorable dimensions for the thermal tempering process (ratio of thickness to edge length). The homogeneity of the thermal toughening was therefore investigated with the aid of a polarizer. Figure 1 shows the isochromates caused by the double refraction of polarized light. The disturbed area spreads over a length of about two to three times the glass thickness. Due to the geometry of the glass samples, only the area in the middle used for the adhesive bond can be considered almost undisturbed.

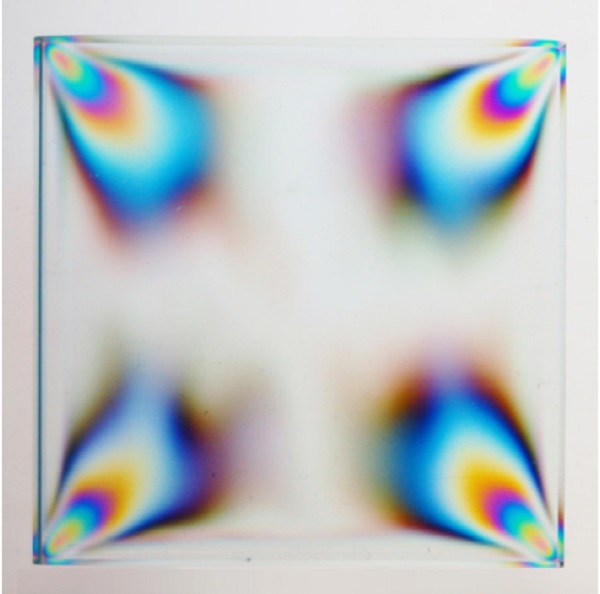

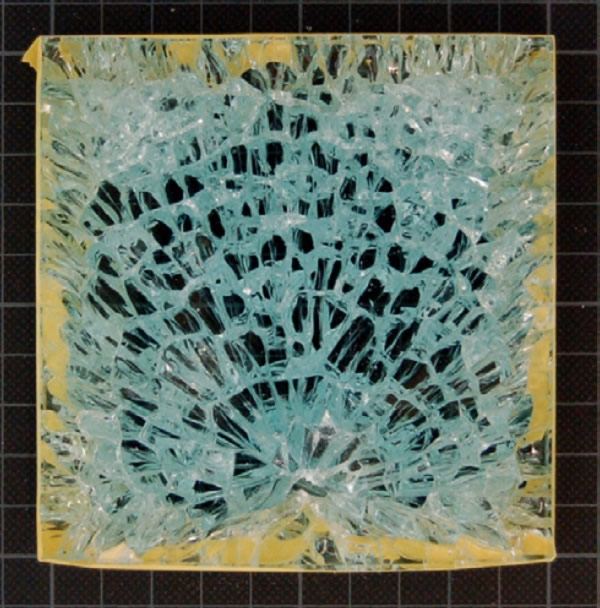

In addition, the qualitative examination of the fracture pattern was also used. Thereby, a typical fracture pattern for toughened safety glass was observed (Figure 2).

Due to the float process, the glass has socalled tin nor atmosphere sides. The tin side is characterized by the presence of tin oxide, which has an undefined influence on the surface properties. Within the investigation program, bonding is therefore carried out exclusively on the atmosphere side.

Stainless steel

One of the outstanding properties of stainless steels is their corrosion resistance under atmospheric conditions. The corrosion resistance is based on a passivatable steel surface. This passivation layer results in an inert surface and leads to the hypothesis of limited adhesive suitability. Despite all this, the adhesive suitability of stainless steels has been proven many times and depends, among other things, on the surface pretreatment as well on the adhesive used. [4, 5, 6]

The metallic joining partners were restricted to stainless steels with German technical approval [7]. Ultimately, the choice of material fell on the stainless steel with the alloy X5CrNi18-10 (material number 1.4301). The reason lies in the sufficient corrosion resistance, in the at least medium machinability and last but not least in the unlimited availability of this alloy both in solution annealed and work-hardened steel grades.

3 Analysis and Experimental Methods

Dynamic Mechanical Analysis (DMA)

The DMA allows the description of the thermomechanical material behavior in good approximation. Statements about the temperature-dependent material behavior are made possible by means of a temperature program run through during the measurement. The analysis method detects state changes that are directly associated with a change in the physical modules particularly sensitively. In the case of polymers, these are relaxation transitions such as the glass transition or the melt of the crystallites.

These are characterized by clear module steps in the measurement. A variation of the excitation frequency allows conclusions about possible temporal dependencies. The investigations presented here include the determination of the physical moduli and the phase transitions. The analyzer used has a vertically arranged, variable loading device and allows various deformation modes. The investigations comprise three samples each (rectangles 25x5x0.5 mm), which were excited in tensile mode with seven frequencies between 0.1 Hz and 10 Hz. [8-11]

Tensile properties

The test procedure for determining the tensile properties of plastics is specified in standard EN ISO 527. The specifications concern the test device, the test conditions and the specimen geometry. For plastics, different shapes of shoulder bars are recommended, depending on the material. The specimen geometry of type 1A was used in this study. In the prismatic range of the specimen, a homogeneous stress distributed over the cross-sectional area can be assumed.

Furthermore, the strains in the two transverse directions are unhindered. Various characteristic values can be derived from the determined deformation behavior. Each random sample comprises five test specimens. The test speed selected was 1.0 mm/min. Six test temperatures within the operating temperature range (-20 °C to +80 °C) were taken into account. [12, 13]

Cylinder tensile test

For the determination of the tensile strength of bonded joints, various test methods are described normatively. Here a tensile test method derived from the standard EN 15870 is used for glass-metal specimens. The end surface of the metal cylinder is bonded centrally to the square glass pane. The nominal thickness of the adhesive layer is 1 mm. All surfaces are subjected to a standard cleaning before the bonding is carried out. Then the adhesive is dosed onto the metal cylinder and the glass pane is positioned. [14]

The reference series consists of specimens which have not undergone artificial ageing. For comparison, the other specimens were subjected to a total of ten different methods of environmental simulation (Table 1). Both the specimens for determining the initial strength and the specimens for determining the residual strength are conditioned for at least 24 hours in a normal climate (+23°C and 50 % rH) before the testing. The destructive test takes place in a normal climate. The specimens are loaded with a constant strain rate until the breaking load is reached.

Spectroscopy and Visual Inspection

The measurements of light technical properties were carried out with an UV/Vis-spectrometer MCS 600 (Zeiss, Germany) using a flash lamp at 245-791 nm as light source. For the measurement both a measuring beam and a reference beam were used. The light entrance and the reference channel are arranged in a photometric sphere, often called the Ulbricht sphere.

The transmission measurement detector is located 10 cm away from the outlet aperture in an angle of 8°. Before actual measurement the system noise was determined via a zero measurement (dark state). Further, a reference measurement with a free light path was done. [15-16] The test specimens consist of two 3 mm thick white glass panes with an inner adhesive layer of 1 mm.

In addition to the spectroscopic investigations, visual inspections were carried out with the test specimens. The specimens were checked for obvious errors before as well after accelerated weathering. The experimental procedure and the laboratory equipment - in particular the lighting conditions - were consistent with the definitions of standard EN ISO 3668 [17].

| Abbreviation | Description |

| FEU | Exposing in condensation-water atmospheres over 500 hours (EN ISO 6270-2, CH-procedure) |

| GEM | Moderate detergent exposure in demineralized water with addition of 0.1 % detergent at a temperature of +45 °C over 500 hours |

| KLI | Exposure to climate cycling over 500 hours (EN ISO 9142, cycle D3) |

| KOR | Corrosion test over 500 hours (EN ISO 9227, NSS test) |

| REI | Exposing in facade cleaner at a temperature of +45 °C over 500 hours |

| SO2 | Exposing in humid atmospheres containing sulfur dioxide over 480 Hours (EN ISO 3231) |

| SUN | Combined exposure to temperature, demineralized water and artificial light for 500 hours (EN ISO 11431 in automatic cycle) |

| TEM | Thermal Exposure at +80 °C over 500 hours |

| UV | Exposure to artificial light over 2000 hours (EN ISO 12543-4) |

| WAS | Exposing in demineralized water at a temperature of +45 °C over 500 hours |

Table 1: Laboratory testing for the simulation of environmental conditions.

Accelerated Weathering

In order to assess the durability and resistance to potential environmental influences, the glass to metal samples and additionally glass to glass samples were subjected to various accelerated weathering methods in the laboratory. The accelerating effects of weathering are based mainly on excessive exposure of the samples. The selected laboratory tests (Table 1) simulate both the individual environmental influences such as temperature, radiation, humidity and harmful media as well as various combinations of these influences. The methodology and scope of the studies are based on normative specifications.

4 Properties of the adhesives

Thermomechanical properties

The following diagrams (Figure 3) show the results of the DMA and represent the mean values of the results for the storage modulus E’. For the preliminary investigation of the adhesives, their modulus values above the glass transition and the initial temperature of the glass transition are important. On the other hand, the characteristics of the glass transition area and the entropy elastic state do not play a significant role. [8]

The material behaviour of the adhesives investigated is temperature-dependent. At the beginning, the storage modulus shows a continuous reduction with a slightly decreasing curve. The thermomechanical behaviour is only marginally frequency-dependent. The significant modulus step, which characterizes the glass transition, is clearly pronounced for all adhesives.

The initial temperature of the glass transition varies between the individual adhesives and is in the range of -5 °C to +47 °C depending on the frequency. The initial temperature of the glass transition of the Scotch Weld DP105 adhesive is below room temperature, which is not very advantageous. Based on the test results, most other adhesives investigated should not be used significantly above room temperature. Only the adhesives Loctite 9483 and Loctite M-31CL show slightly better temperature stability.

![Figure 3: Thermograms of the multi-frequency measurements. [1]](/sites/default/files/inline-images/Fig3_10.jpg)

Tensile Properties of the Epoxies

The determination of the tensile properties provided information on the deformation and fracture behaviour of the adhesives. The diagrams (Figure 4) have an identical area of representation. If a test specimen breaks within the represented area, then the mean value curve is only displayed up to the lowest elongation achieved. As expected, the results depend on the test temperature.

At low temperatures the epoxies have a high modulus and high strength. Within the glass transition area, the properties change significantly and there is a clearly recognizable softening of the adhesives. The behaviour of the epoxies investigated ranges from almost linear-elastic with spontaneous fracture failure to elasticplastic with fracture elongations of sometimes more than 50 %.

The entropic elastic state at high temperatures is characterized by low modulus of elasticity, low strength and usually higher elongation at break. The tensile properties generally follow the results of the DMA. When comparing the test methods with each other, the adhesives Araldite 2020 and Loctite Hysol M-31CL stand out above all.

At a test temperature of +60 °C, both achieve Young’s moduli of about 1,200 MPa and mean breaking stresses of 17 MPa and 19 MPa respectively. In this case, post-curing during conditioning of the specimens can be assumed. For a test temperature of +80 °C, no adhesive achieves modulus or strength values of any appreciable size.

![Figure 4: Tensile stress-strain diagrams as a function of the test temperature. [1]](/sites/default/files/inline-images/Fig4_11.jpg)

5 Behaviour of Adhesive Joint

Strength of Glass-and-Metal Joint

The epoxy resin adhesives adhere well to very well to the cleaned stainless steel and glass parts.The 5 % fractile of the initial fracture strengths lies between 5 MPa and 15 MPa. However, the individual epoxy resin adhesives and their bondings react differently sensitively to the artificial weathering. In particular, the weathering methods, which are associated with water or harmful media, were frequently accompanied by strength reductions.

On the other hand, irradiation with artificial light or exposure to high temperatures in most cases had little effect on the strength of the compound. The adhesives Araldite 2020, Loctite Hysol 3430, Loctite Hysol 9483 and Loctite Hysol M-31CL show good residual breaking strengths except for a few random samples. The examination of the detailed results shows, in addition to the high fracture strengths, the sometimes considerable variations of the results within a test series. These have clear effects on the determination of the fractile values.

Photometric Characteristics and Visual Assessment of Glass–to–Glass Samples

In addition to durability in terms of mechanical properties, the durability of optical properties and appearance were investigated. The results of the UV-/Vis-spectroscopy are described below. The calculation of this degree of light transmission is based on the method outlined in standard EN 410 [18]. The degree of light transmission depends on the kind of accelerated weathering exposure.

The Table 2 shows the relative changes of the transmittances for the spectral range of visible light. The given results represent the relationship between the transmittance after exposure to the transmittance before exposure. Spectroscopic observation also makes it possible to detect barely visible changes. The results of the measurements were particularly remarkable for the increased temperature and artificial light exposure. Thus, with all epoxy resins there is a significant reduction in transmission. The results of the transmission measurement are inconspicuous for the other accelerated weathering.

![Table 2: Relative change of light transmittance after accelerated weathering. [1]](/sites/default/files/inline-images/Tab2_0.jpg)

The results of the fault investigation by visual assessment are shown in Table 3. Discoloration and delamination occurred as obvious types of faults. Further defects such as blistering or turbidity were not observed. Six of the eight adhesives are characterised by a high transparency before the artificial weathering. They are clear and colourless. Only adhesives Araldite 2011 and Scotch Weld DP 110 are semi-transparent. Especially photochemical ageing, causes by solar exposure or by artificial light source, can lead to significant visual changes like discolorations.

![Table 3: Visual inspection after accelerated weathering. (V: distinct discoloration, v: minor discoloration, D: complete delamination, D: large-scale delamination, d: localized delamination at the edges). [1]](/sites/default/files/inline-images/Tab3_0.jpg)

The color changes range from light yellow to dark brown. The effects are less noticeable when exposed to high temperatures. A few adhesives have more or less pronounced delaminations. These delaminations occur primarily in contact with moisture or cleaning agents. In three cases (GEM, REI, WAS), the adhesive SW DP 105 suffered completly loss of adhesion.

![Figure 5: Initial and residual fracture strengths of the glass to metal joints. [1]](/sites/default/files/inline-images/Fig5_12.jpg)

6 Summary

Transparent adhesive systems used in glass constructions and in facades have to fulfill special demands on the durability of their mechanical properties as well as on their optical quality. A total of eight epoxy resin adhesives and their bonding were examined and compared on the basis of extensive criteria in order to obtain a maximum possible complete overview of the adhesive group. In addition to thermomechanical and mechanical properties, the experimental studies also paid special attention to optical properties and appearance. Ten environmental simulation methods (see Table 1) were included in the program for the analysis of weather resistance.

7 Acknowledgement

We thank the German Federal Ministry for Education and Research (BMBF) for the funding of the research project GLASKONNEXTransfer and all our industrial partners involved in this project for collaboration.

8 References

[1] Wünsch, J.: Transparente Epoxidharzklebstoffe für Glas-Metall-Verbindungen - Transparent Epoxy Resin Adhesives for Use in Glass-to-Metal Joints, 2 volume set. Dresden: Technische Universität Dresden, 2017.

[2] Müller, B.; Rath, W.: Formulierung von Kleb- und Dichtstoffen. Hannover: Vincentz, 2009.

[3] Petrie, E.M.: Epoxy Adhesive Formulations. New York, McGraw-Hill, 2006.

[4] Geiß, P. L. et al.: Merkblatt 382. Kleben von Stahl und Edelstahl Rostfrei. Düsseldorf: StahlInformations-Zentrum und Informationsstelle Edelstahl Rostfrei, 2012.

[5] Weller, B.; Kothe, C.; Wünsch, J.: The Stability of Surface Pretreatments on Different Stainless Steels. In: 10th European Conference on Adhesion. Alicante, 2014.

[6] Kothe, C.: Oberflächenvorbehandlung von Fügeteilen zur Optimierung adhäsiver Verbindungen im Konstruktiven Glasbau - Surface Modification Methods for Improving Adhesive Joints in Glass Structures. Dresden: Technische Universität Dresden, 2013.

[7] Z-30.3-6, April 2009: Erzeugnisse, Verbindungsmittel und Bauteile aus nichtrostenden Stählen. Allgemeine bauaufsichtliche Zulassung. Düsseldorf: Informations-stelle Edelstahl Rostfrei, 2009.

[8] Ehrenstein, G.W.; Riedel, G.; Trawiel, P.: Praxis der Thermischen Analyse von Kunststoffen. München, Wien: Hanser, 2003.

[9] Menard, K. P.: Dynamic Mechanical Analysis: A Practical Introduction. Boca Raton: CRC Press, 1999.

[10] EN ISO 6721-1:2003.

[11] ISO 6721-4:2005.

[12] EN ISO 527-1:2012.

[13] EN ISO 527-2:2012.

[14] DIN EN 15870:2009.

[15] Bass, M.: Handbook of Optics, 5 volumes set. 3rd edition. Columbus: McGraw-Hill, 2010.

[16] ZEISS: Multi Channel Spectrometer MCS 600. Jena: Carl Zeiss MicroImageing, 2007.

[17] EN ISO 3668:2017.

[18] EN 410:2011.