Date: 21 February 2013

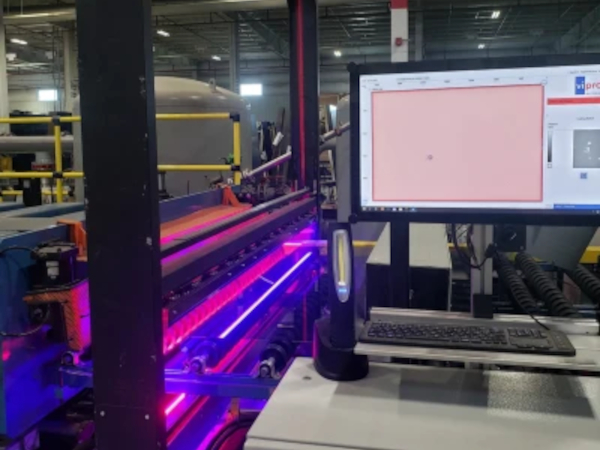

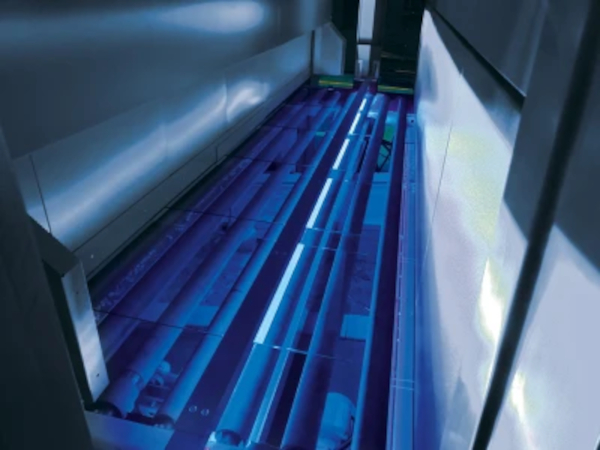

Yantai Changyu glass, the leader and most advanced Chinese container manufacturer (500,000 ton per year, 7 furnaces in Shandong province) makes one more step toward high-quality and secure a leading position for export and local market with TIAMA french latest technology of automatic inspection machines MCAL4, MULTI4 and MX4 machines, having now up to 52 inspection machines. This new project is another confirmation that Yantai Changyu glass using exclusively imported from France TIAMA inspection is the most successful supplier of high quality bottles for wine, spirits, any beverage and food containers in China. The state of the art inspection equipment from TIAMA ensures the automation of job change as well as a constant quality level for all type of containers.

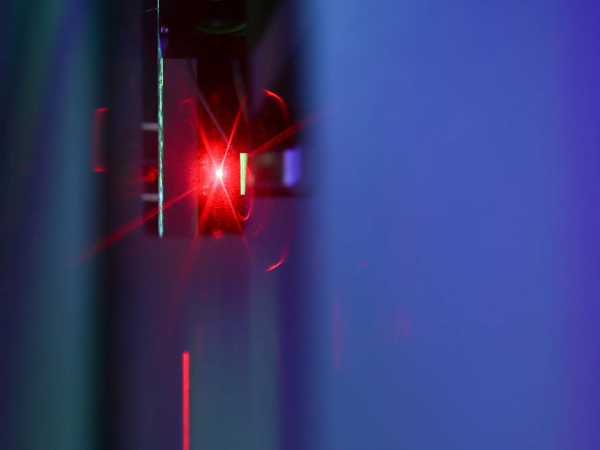

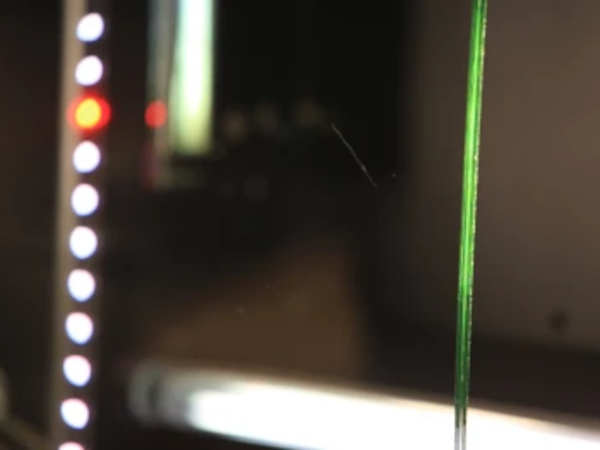

The unique technology developed by TIAMA is the most advance intelligent software and learning product standards such as ATLAS (automatic check detection based on advance digital camera technology) which can ensure the highest detection of critical defects, repeatability and a constant level of quality.

Yantai Changyu glass strategy is shaking glass industry worldwide with a constant improvement in quality and process automation using world most advance technology made in France by TIAMA“

TIAMA press release 18/02/13

2013-02-21T12:00:00

Yantai Changuy Glass continues to invest in TIAMA msc & sgcc inspection machines

glassonweb.com

Add new comment