Latest news

196 results

| Glaston CHAMP EVO represents the latest evolution in the CHAMP automotive glass pre-processing line.

| For over 60 years, LiSEC has been producing glass processing machines, offering innovative single and system solutions in the field of flat glass processing and refining.

| With a strong partnership to optimised solutions for more efficiency in "shop floor logistics"

| This year Felbermayer started its own insulating glass production and LiSEC was allowed to support the company with this project.

| Alongside many machines operating in real time, booth A55 in hall 14 has much to offer.

| Surplus Solutions in conjunction with Joseph Finn Company will conduct a major online auction to sell the assets of Solar Seal

| Troostwijk announces an Online Auction closing Thursday 25.08.2022

| TUROMAS, Spanish manufacturer of flat glass machinery participates as exhibitor in the last edition of Glass South America.

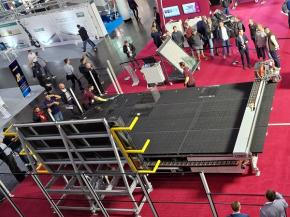

| CMS’s runner line is available in two sizes: half Jumbo and Jumbo.

| Flat glass is great material to use for interior furnishings. Using monolithic or laminated glass, a myriad of different products can be produced.

| The HEGLA ProLam LSR increases LSG cutting productivity by up to 20 percent.

| Interview with Vicente Cervera, president of Cerviglas.

| Since the installation of a HEGLA Optimax cutting table and a fully automated Rapidstore system at Custom Glass, the company has gone from strength to strength.

| Fully automated, high performance cutting line for XXL 18 meters glass sizes.

| To further expand its services for the North American market Airborne, the technology leader in automated and digital manufacturing of advanced composites, is pleased to announce the appointment of Eastman Machine Company as a Preferred Reselling…

| With cutting and automation solutions from HEGLA, you achieve maximum productivity with perfect edge quality.

| Fastest laminated glass cutting on the market, thanks to the efficient, highly automated VSL-A system solution from LiSEC with Dynamic Load Balancing (DLB)!

| In today's video, LiSEC's experts present you some highlights of the LiSEC loading and cutting systems.