Photo source

Glaston Corporation

Date: 8 April 2024

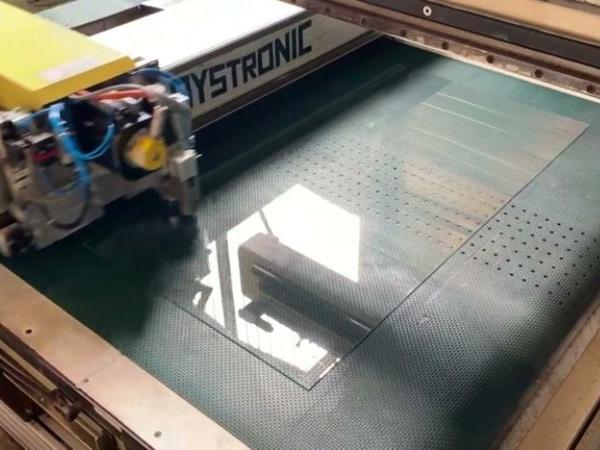

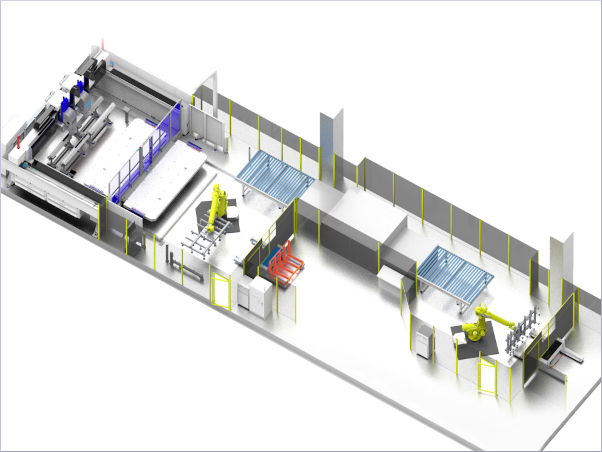

Interested in giving your existing glass-cutting equipment a new life? Glaston CNC96 retrofit is an in-house system engineered with exclusively developed hardware components used from 1996 until 2010.

This video shows how you can retrofit your existing, former Bystronic glass automotive and architectural glass-cutting equipment, using a CNC96 control with a state-of-the-art CN control including the most modern features.

More about the solution: https://glaston.net/upgrade/upgrade-kit-cnc96-retrofit/

600450

600450

Glaston Corporation

2024-04-08T07:55:00

Retrofit your existing glass cutting equipment with proven Glaston OEM upgrade kits

glassonweb.com

Add new comment