Others also read

Glaston SPEED is a quick insulating glass manufacturing line family that produces triple and quadruple units in the fastest possible cycle times.

Personnel dedication of NorthGlass customer service and excellent performance of the furnace have been recognized by customers.

The project is under the leadership of the Fraunhofer Institute for Experimental Software Engineering IESE in Kaiserslautern.

The meeting point between Mappi and Somec was an ATS 4.0 tempering furnace.

A letter of thanks from Germany for the technical upgrading of a SC-1B42 tempering furnace.

From ashes to flagship FC Series - Custom Glass UK orders Glaston’s FC Series tempering furnace line

Today's video is all about the LiSEC TPA - the fully automatic system for applying thermoplastic spacers. Don't miss this expert talk!

To increase their productivity and to give their customer an ever better product, Glasskon has installed two insulating glass lines by Forel.

2020 - Looking back on what we have gone through together

The upgrades will be delivered and installed in March 2021.

Glaston Group has closed a deal for a FC Series™ tempering line with one of the largest suppliers of turn key sunrooms in North America.

Glaston has closed a follow-up deal with Lippert Components Inc. for an automotive pre-processing line and an insulating glass line.

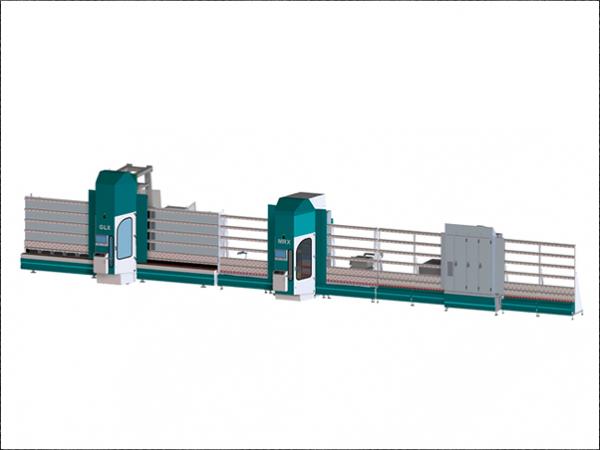

combiFIN is a compact but simultaneously highly efficient vertical processing line for flat glass with a thickness of typically 4 to 12mm.

Glass Futures opens a virtual door to it Global Centre of Excellence - be part of our open design sessions.

A MappiSUPERTEMPER™ tempering furnace achieves the characteristics necessary to certify E30 glass for fire resistance.

The “High Tech” IG line have evolved from the best of Forel’s latest equipment, mainly dedicated to the production of double, triple and even quadruple insulating glass units for both residential and commercial architecture.

Glaston Group has closed a deal for three insulating glass lines with one of the leading architectural glass suppliers in China, CSG Holding Ltd.

Window Creations choose ATS Mappi tempering furnace.

NorthGlass Tempering Furnace BU exceed 15 million USD sales and 40 orders in both October and November.

It could be in 2022. The proposal to proclaim the 2022 as International Year of glass is currently being examined by the United Nations General Assembly.

Mappi International has won the 2020 USGlass Readers’Choice Award for Machinery - Tempering Equipment with Industry 4.0 Tempering solutions, now enhanced with “Powered by Siemens” improvements.

How can you prolong the lifetime of your equipment? Find out in LiSEC's new video!

Launching New Zealand’s state-of-the-art facility for advanced insulated glass units

How does LiSEC.eye work? What advantages does LiSERV offer? Answers to these questions and much more information can be found in the new video.

In October effective tempering furnace orders were 40 and its total amount of nearly 21 million dollars.