Others also read

Mark Hickox, Sales Director at Thermoseal Group, reflects on a transformative 2025 and shares how international growth is laying the foundations for a stronger, more efficient operation at home.

Thermoseal Group boosts efficiency and export readiness with a new automated banding and collating machine for its Thermobar spacer bars.

FENZI merges cutting-edge automation with architectural adaptability through its certified warm-edge spacers—Butylver TPS and Thermoflex—delivering sustainability, efficiency, and creative potential to modern IGU production worldwide.

Thermoseal Group will be exhibiting alongside its parent company, Fenzi Group, at a series of leading international glass industry events in 2025.

Thermoseal Group manufactured 60% more Thermoflex in July compared to June, reflecting a growing demand for the company’s UK-manufactured warm-edge solutions, in both domestic and international installations.

Proposed standard ensures consistent evaluation of edge effects when sealants contact glass interlayers.

Thermoseal Group’s Sales Director, Mark Hickox, explains why having an in-house lab is vital to the component manufacturer’s success.

Thermoseal Group has reported that the UK spacer bar market is experiencing a key change, with window manufacturers moving away from the once dominant 20mm airspace towards a broader mix of sizes.

Thermoseal Group’s Sales Director, Mark Hickox, explains how cost-cutting with a low-quality hot melt sealant can lead to expensive long-term failures.

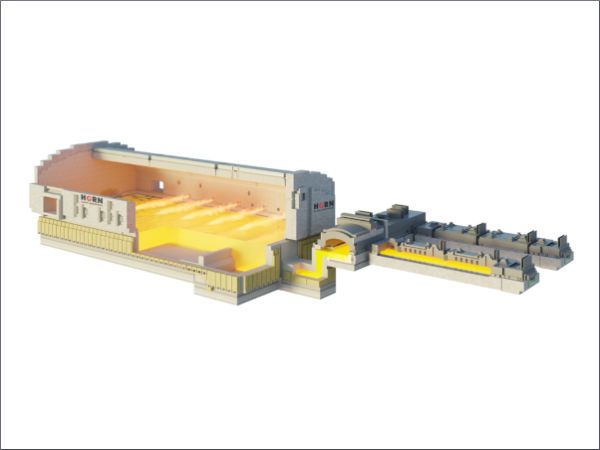

Two strong companies that are committed to innovation: Gerresheimer and HORN Glass Industries AG rely on state-of-the-art glass melting furnace for enhanced efficiency and sustainability.

Fenzi Group’s range of sealants specifically formulated for high-performance IG Units ensures maximum durability, energy efficiency, and long-term reliability.

Butylver TPS, Fenzi Group’s advanced thermoplastic spacer for Insulating Glass Units, has officially obtained CEKAL certification.

A new end fired glass melting furnace will soon be built for Sichuan Skyhorse Glass Co., Ltd by HORN.

Thermoseal Group’s Sales Director, Mark hickox, explains why the knowledge and experience of your supplier’s team can be just as valuable as the products they provide.

As part of the Fenzi Green Future Action Plan, Fenzi Group strengthens its commitment by achieving EPD for its entire IG sealant range.

Thermoseal Group has raised questions over market consolidation in the UK in response to advancing automation, a trend already seen elsewhere in Europe.

HORN has successfully designed and supplied a cutting-edge oxyfuel furnace for Orora Group, enhancing sustainable glass production in Australia.

Gerresheimer contracted the glass melting technology specialist HORN to replace the existing furnace and to convert it to the latest low-CO2 glass melting technology.

Over three-quarters of all products sold by specialist IG component maker and distributor, Thermoseal Group, were manufactured in-house at its UK sites, in 2024.

We are thrilled to announce that you can now configure Swisspacer, Saint-Gobain products directly in Calumen®, the reference glass calculator by Saint-Gobain Glass!

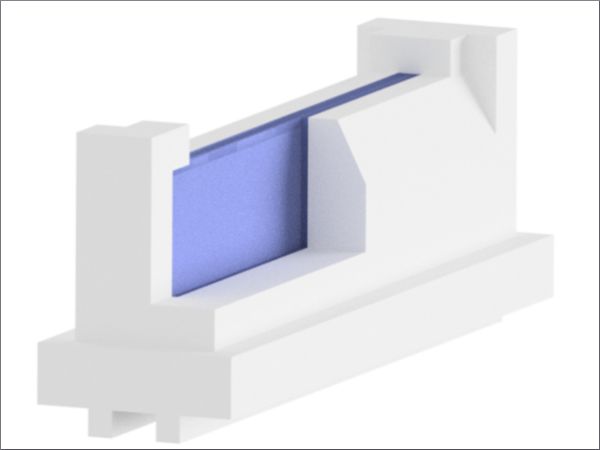

The molybdenum wall is a crucial component in melting furnaces, enhancing glass quality by preventing short-circuit flow and ensuring optimal refining processes.

Auer Lighting GmbH continues to set benchmarks with innovative and sustainable solutions.

In March, HORN announced its collaboration with Ambev to supply a state-of-the-art, energy-efficient glass melting furnace equipped with three forehearths for Ambev's new container glass plant in Brazil.

The Fenzi Group is proud to showcase a legacy of innovation and quality, with advanced technologies that address market demands for high-performance and sustainable glass solutions.

Thermoseal Group’s new innovations and machinery proved to be a smash hit at this year’s Glasstec Exhibition in Dusseldorf, held between October 22-25, 2024.