Others also read

To support ambitious growth plans, the Dutch company Buys Glas didn’t just expand its production space, they invested in smart automation.

On the occasion of MECSPE 2026 (BolognaFiere, 4–6 March), Tecnest presents itself as an integral part of the Scm Group digital ecosystem, aimed at strengthening its technological offering dedicated to the manufacturing sector.

Glaston has entered into a cooperation with Leadus, a specialist in vacuum insulating glass (VIG) technology, to further develop advanced glass manufacturing solutions.

Soft market continued, profitability supported by productivity improvements.

The ultimate glass lamination machine to laminate with EVA, PVB and SGP.

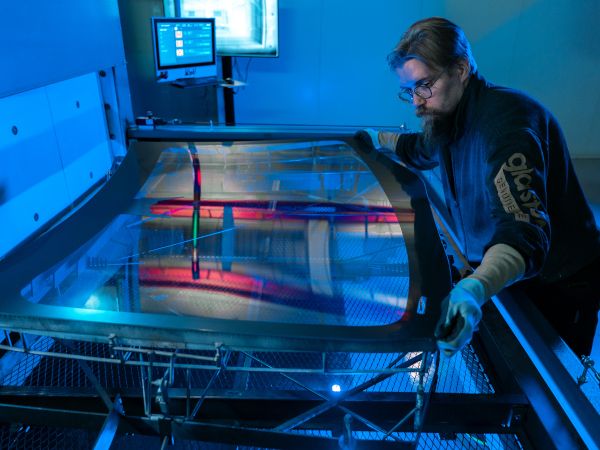

Knowing its roots helps shape the future. From Tamglass in the 1970s to Glaston today, the company’s windshield-bending journey has been driven by curiosity, craftsmanship and teamwork.

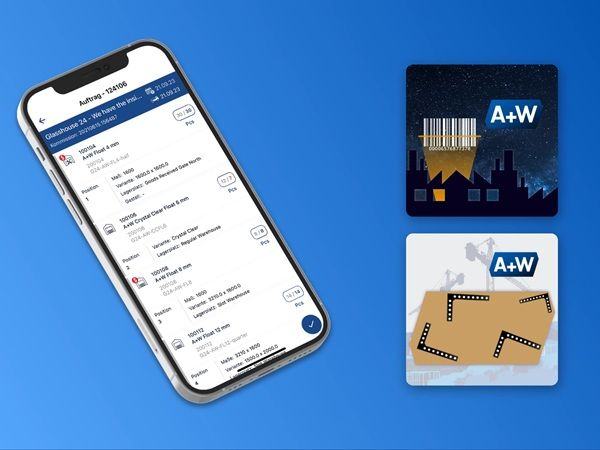

Kensington Glass builds smarter and more precisely by pairing craftsmanship with the power of A+W Software.

Glaston supports the more demanding automotive glass market with advanced processing technologies and consistently superior optics.

HEGLA-HANIC redefines how glass companies manage orders with an industry-specific Microsoft Copilot assistant.

As 2025 draws to a close, it’s a good time to reflect on business. We know for most glass processors, this has not been the easiest year.

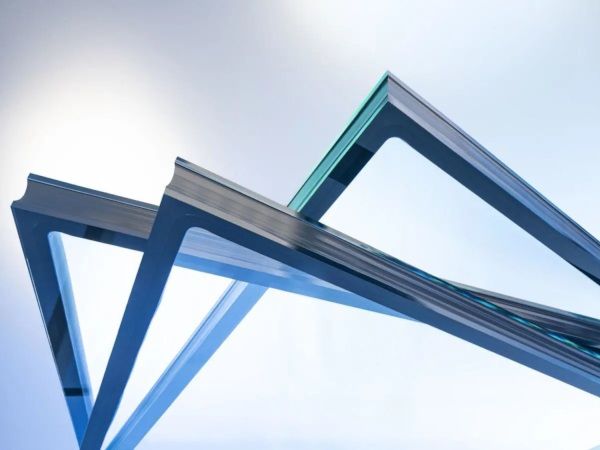

Discover how the new Glaston TPS® PRO technology sets a new benchmark in insulating glass manufacturing.

A Transformative Leap in Automated Order Management for the Glass Industry

A forward-looking collaboration between NBS and Forel shows how automation and large-format glass production are redefining the future of industrial glass manufacturing in Japan.

HEGLA is expanding its portfolio by entering the field of wet glass machining through the acquisition of RS technology, strengthening its capabilities in advanced glass processing and automation solutions.

Changing software is an opportunity to show how the right partner, process, and mindset can turn uncertainty into lasting growth.

LiSEC is meeting challenges and emerging trends with innovative concepts and custom solutions.

R.C.N. Solutions celebrates its long-standing partnership with Vetreria Ascolese — a company that combines tradition, innovation, and excellence in glass manufacturing.

A+W Software is set to showcase its latest digital innovations for the glass, window, and door industries at Windows, Doors & Facades 2025 in Dubai.

Scm Group wins the SMAU Innovation Award for “Smart Spindle” — an AI-powered system that predicts faults, cuts downtime, and boosts efficiency.

The strengths and expertise of the MADE products to date will be bundled under the LiTROS brand, developed further and opened up to new target markets.

A+W Software is excited to unveil Mira, its new AI assistant designed to transform inbound order management for glass, window, and door manufacturers.

Uniglass Solutions Oy, part of the Glaston Group, has appointed Pyry Ollonqvist as General Manager, effective November 1, 2025.

Improved net sales and profitability, challenging market conditions continued

Explore how Glaston is reshaping the customer experience.

With its new plant in Port Talbot, Press Glass UK is consolidating three locations and boosting efficiency and growth thanks to LiSEC automation.