Others also read

NovaSklo signed an agreement with Pilkington Technology Management Limited (NSG Group), the global leader in glass manufacturing technologies.

Accurately measuring argon in insulating glass units (IGUs) is essential to ensure energy efficiency and sustainability—here’s how advanced testing methods, including Sparklike solutions, make it possible.

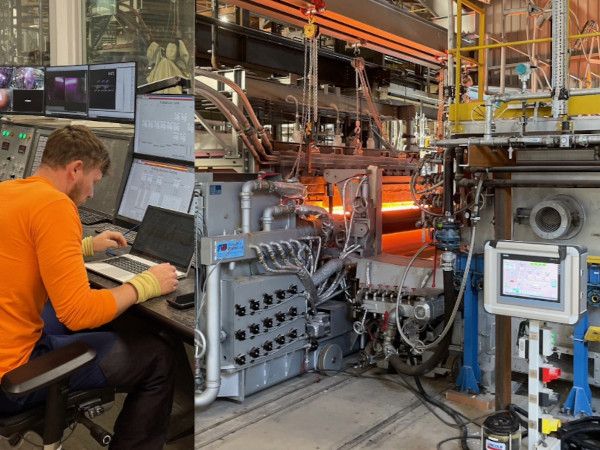

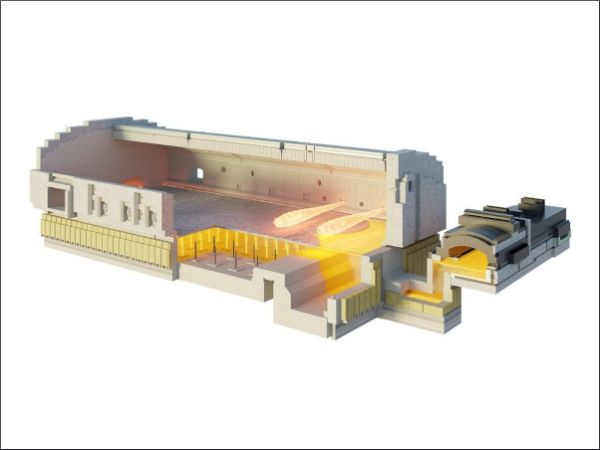

NSG Group has launched a new rolled glass production line at Pilkington UK’s Greengate Works, marking a key step in sustainable glassmaking.

Learn how to get the most accurate results with Sparklike Laser devices for non-invasive IGU gas concentration measurement.

Pilkington UK has launched a new glass production line at its Greengate Works site in St Helens as part of a multi-million-pound investment to safeguard the future of rolled texture glass manufacturing in the UK.

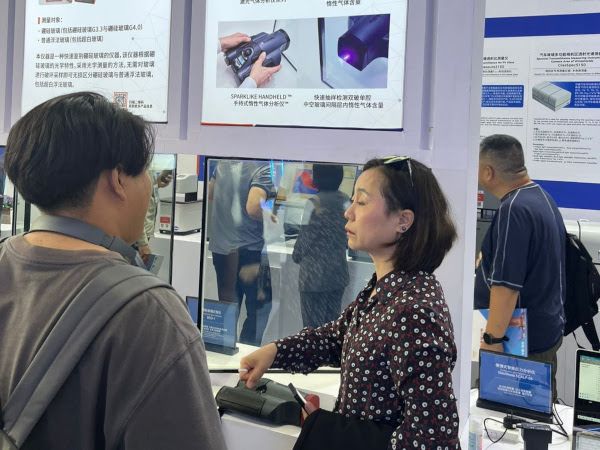

Sparklike launched the 2025 trade fair season with key appearances at China Glass 2025 in Beijing and Glass Performance Days in Tampere.

As one of the leading glass manufacturers in Europe, Pilkington Poland, part of the global NSG Group, places high emphasis on quality and performance.

Making sure insulating glass units (IGUs) meet high standards is essential for both manufacturers and installers. The gas fill level in IGUs is key to providing good thermal performance and energy efficiency.

The latest evaluation by ift Rosenheim confirms that the Sparklike Laser Portable 2.2™ meets the accuracy requirements of EN 1279-3 for measuring gas concentrations in insulating glass units (IGUs).

In the production and quality control of Insulating Glass Units (IGUs), maintaining consistent gas concentration readings is important to maintain its properties.

Vasglass continues to push the boundaries of quality and innovation. Here’s how they tackled a key challenge in insulating glass verification.

A recent evaluation by ift Rosenheim has validated the performance of the Sparklike Handheld 3.0™ for measuring gas concentration in insulating glass units (IGUs).

Longer lifetime, higher reliability

In the production of insulating glass units (IGUs), precise control over the gas filling process is critical to maintaining product performance.

Addressing the industry’s decarbonisation challenge, HORN is taking the next step forward in the industry´s transition to a resource-efficient and low-carbon economy.

NSG Group is pleased to announce that Pilkington United Kingdom Limited, part of NSG Group, intends to use green hydrogen at its site and scale its production of low carbon glass from 2027, under pioneering new plans with Grenian Hydrogen.

This article explores the various types of insulating gases, their thermal performance, and their contribution to energy efficiency.

Asahi India Glass & INOX Air Products collaborate for an industry pioneering initiative with a 20-year agreement for off-take of Green Hydrogen at Asahi India’s Chittorgarh Plant

Argon concentration plays an important role in the performance of Insulating Glass Units (IGUs), impacting their insulation capabilities and energy efficiency.

Sparklike's new customer case offers an intriguing look at how the latitude affects argon gas retention in IGUs. This is crucial for energy efficiency and thermal performance.

Pilkington Nederland BV has recently taken a significant step forward in quality assurance by incorporating the Sparklike Laser Portable™ into their production process.

In the ever-evolving landscape of sustainable living and energy efficiency, the Glass for Europe manifesto for 2024-2029 emerges as a guiding light towards a greener future.

In this blog post, we delve into the profound impact that precise gas measurement has on insulation performance and explain why it is a game-changer for manufacturers in the industry.