Date: 14 July 2011

On recommendation Edmund Howes, Managing Director of the Aylesbury based company, reviewed the product range available from the leading glass machinery distributor and chose to invest.

Having established a strong reputation for quality with the high end sector of the glazing industry, it was imperative that only the most reliable equipment be installed for Quickseal’s current expansion programme.

Quickseal Ltd was established 18 years ago to provide niche products to the glazing industry. During this time the company has seen consistent and steady growth as a specialist manufacturer.

The decision to invest in products from The Glass Machinery Company came at a time of natural progression and growth as senior management wished to begin in-house manufacturing regarding certain products whilst also reducing turnaround times.

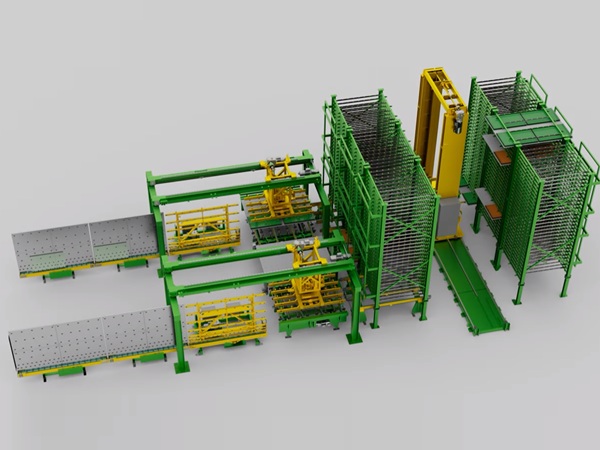

The desire to expand has resulted in the need to streamline the production process with the purchase of a new Fratelli Pezza Mistral M120V sandblasting machine which is further automating the company’s facilities. The Mistral has an automatic or manual, numeric-control sandblasting cabin as well as entry and exit glass supports, each being 1.400 mm. in length. Additionally there is an automatic 4.000 mm long conveyor belt which is lined with a special material that is both wear proof and cut proof. Stepped movement of the Mistral 120’s glass plate is programmable according to the type of sandblasting required, with the ability to set the movement in a continuous motion.

Having carefully researched products on the market, the fully automated equipment from The Glass Machinery Company has made substantial improvements to on-site efficiency at Quickseal since its installation with production times increased.

Edmund Howes was extremely impressed with the quality of standards provided by the service installation team as the machinery was delivered and installed with minimum disruption to ongoing manufacturing procedures. Edmund Howes comments: “Making investments in machinery is a decision that must be measured and considered carefully. Having established a reputation for reliability and quality it is vital that we maintain these standards for our customers as Quickseal expands. In respect of the quality and reliability of the equipment, we have not been disappointed and equally The Glass Machinery Company team has excelled regarding both installation and efficient after-sales care services. I would highly recommend the team and the products.”

Darren Bill, Sales Manager at The Glass Machinery Company comments, “It is reassuring to know that we can support our customers and give complete peace of mind regarding our product range. Being recognized for our quality standards is rewarding and demonstrates that we are providing the right products and services to the industry.”

Add new comment