Date: 27 November 2018

When it comes to building business relationships both Steve Powell and Steve Goble are meticulous when planning strategies that will help to build their customers’ business.

Steve Goble comments, “Focus this year has very much been about faster output and more efficient production methods with processors looking to diversify and offer more from under one roof to satisfy a fluctuating market on both domestic and commercial sectors.”

Now is a time when everyone evaluates the successes of the last 12 months and with service and customer support always the highest priority, both companies have seen very positive results.

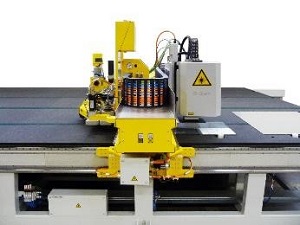

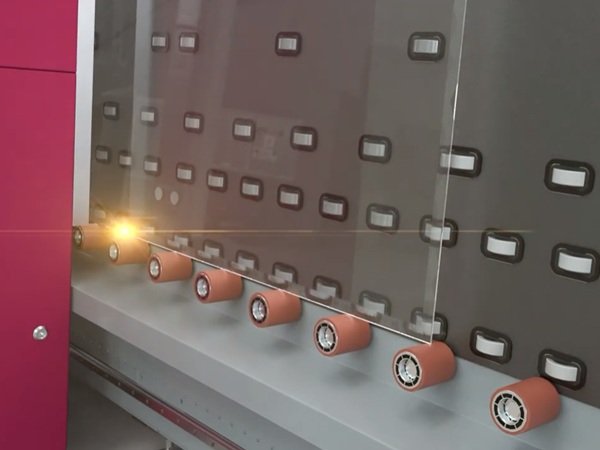

Laser-marking and triple unit manufacturing have been a big focus for many customers across the UK. Next year’s projects and capital investments already look extremely positive for both Bystronic glass and HEGLA.

Laser-marking and triple unit manufacturing have been a big focus for many customers across the UK. Next year’s projects and capital investments already look extremely positive for both Bystronic glass and HEGLA.

Developments in AI and merging digitisation into slick, automated processes will inevitably become most manufacturers focus. It is expected that smart technology in glass will also become a priority as biometrics and machinery become more closely intertwined.

Providing customers with viable support and keeping the production flow at optimum levels requires consistent maintenance and technical support.

“The Bystronic glass team is committed to keep machinery from the range working at its best and provides excellent technical support. Regular servicing reduces breakdown and ensures costs can be saved over the life of the machine. This type of contractual agreement has proved popular this year with many customers realising the longer term benefits in relation to spares and service.” Steve Powell, Managing Director, Bystronic glass UK comments.

Both Managing Directors recognise the importance of developing tailored solutions for customers to create viable avenues of growth for glass processors as the market heads towards a faster, more digital future.

Knowing that a company fully grasps how to achieve a high level of production performance with the investments in machinery that they make is vital.

It is evident that next year will bring even greater change to the glass machinery sector and that it is an industry that is changing rapidly. There has been significant investment in machinery from both companies throughout 2018 and this is a trend that is set to continue as we head towards the new year.

Looking ahead, Steve Powell sees a positive market with customers enjoying the benefits of lean manufacturing that will place them ahead of competitors.

According to Steve Goble manufacturers have greater control than ever before over the whole production process which is a clear advantage that can be passed down to their customers, in relation to more efficient manufacturing, quality control and delivery time.

As the year draws to a close the Bystronic glass HEGLA UK partnership remains strong and confident with an optimistic outlook and orders already placed for 2019.

600450

600450

Add new comment