Date: 27 October 2017

With effect from July 2017, a large number of fire resistance tests and smoke tests have been conducted on doors, gates, facades, glazing or fire safety curtains in the technology centre – and, as a matter of fact, in accordance with German, European and international regulations.

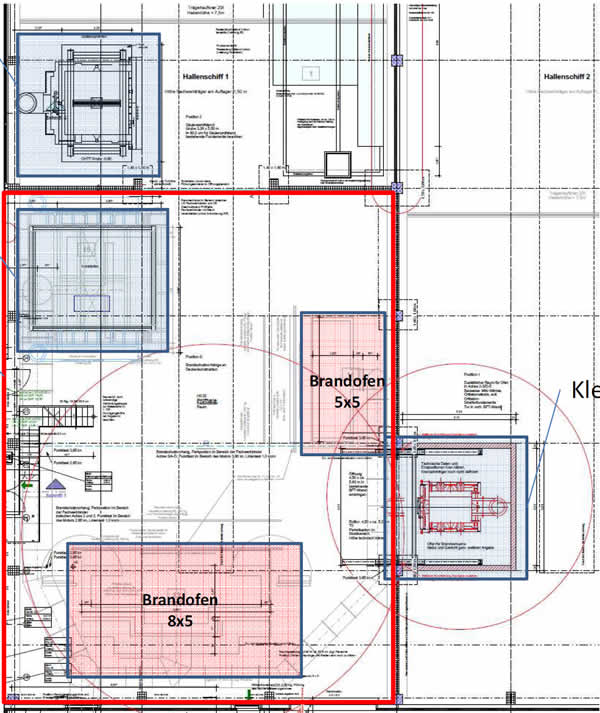

Apart from the 8 x 5 metre large furnace, even the proven 5 x 5 metre furnace from Nuremberg is now operational again. Starting from the beginning of 2018, two more furnaces will be added for load-bearing pillars, ceiling beams and floor structures as well as one small furnace.

Together with the durability and smoke test rigs, manufacturers also receive all necessary tests and certificates for reaction to fire, fire resistance, smoke control as well as spreading of fire – from a single source. Based on the cooperation with the internationally popular fire specialists UL, the slogan "Tested in Rosenheim – certified for the world" applies.

All over the world, fire safety and smoke control are important requirements for structures, especially for buildings in which larger gatherings of human beings are expected. This includes larger residential constructions just as much as public buildings, sports and production facilities.

Those who offer windows, doors, gates, facades and construction materials for such structures, generally also find requirements for reaction to fire, fire resistance and smoke control in the specifications (Bill of Quantities). If the manufacturer cannot supply the required verifications, there is generally the likelihood of being excluded from the contract award procedure.

This is why internationally recognised tests and certificates are of great significance for the manufacturer. Hence, ift Rosenheim has inaugurated a new fire safety centre in 2016, designed for fast and efficient testing. All necessary fire tests as well as smoke control and durability tests can be carried out.

"Building block boxes" and professional logistics facilitate efficient and economical set-up of the test specimens. The close cooperation of UL with ift experts in conjunction with comprehensive testing capacities at Rosenheim offers manufacturers not only easy coordination for tests, but also for verifications and certifications for European and international markets.

To consolidate the options and facilities for testing, the fire safety centre is now being further expanded and supplemented by the neighbouring UL laboratory. The following five furnaces will be available by March 2018.

1+2: Testing the fire resistance of walls, doors, fire protection systems, facades etc. in the dimensional (W x H: 8 m x 5 m as well as 5 m x 5 m),

3: Combination test rig for load-bearing bars, roofs, dampers, ventilation ducts as well as pipe claddings with a load imposed by 16 cylinders of 5 tonnes each in the dimensional (W x H x D: 4.0 m x 5.0 m x 2.5 m),

4: Testing of load-bearing and non-load bearing supports up to a load of 500 tonnes in the dimensional (W x H x D: 3 m x 3.2 m x 3 m),

5: Testing of reaction to fire in accordance with DIN 4102-2 and EN 1363/1 in the dimensional (W x H x D: 1.5 m x 1.5 m x 2 m).

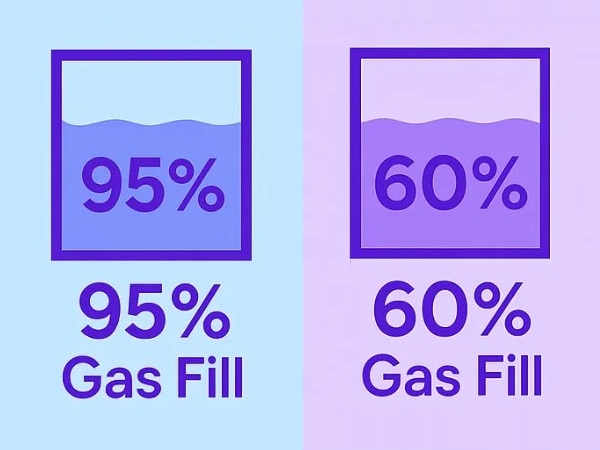

The furnaces and controllers are designed, erected and calibrated by the ift subsidiary "MessTec". Modern furnaces are constructed with the help of comprehensive know-how in programming, instrumentation, electronics and furnace building, with which you can achieve different temperature curves, for example, according to STC, ISO 834, HC, RWS and UL 1709. All burners can be controlled independently such that even unique fire situations can be adjusted and emulated.

In addition, there will also be two smoke control (5 m x 5 m und 3.5 m x 3.5 m) and one smoke tight test rig (10 m x 7 m)) as well as durability test rigs with sizes up to 9 m x 5 m. With this, the ift fire safety centre is one of the most modern laboratory systems in the world so that better justice gets done to the slogan "Tested in Rosenheim – certified for the world".

600450

600450

Add new comment