Date: 8 October 2002

Messrs. Schindler GmbH & Co. Fenster Fassaden Innenausbau KG from Roding, Germany (www.schindler-roding.de), had to tilt in the elements via the available slots into the holding angles under the ceiling. For this it was necessary to swing the element in an inclined position from below with the slot over the pre-assembled angles. Not easy work at a weight of up to 600 kg.

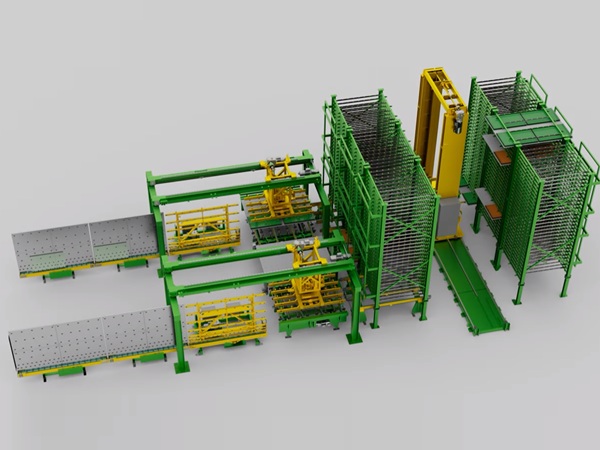

Messrs. Schindler GmbH & Co. Fenster Fassaden Innenausbau KG had chosen with us, the right partner in order to construct a mounting lifting device for this task. For this, the vacuum lifting device Balance was further developed. It then allowed a ceiling projection of ca. 1500 mm and a maximum weight of 1000 kg. The vacuum lifting device Balance has a movable counterweight. To make the device ready for the construction site, the travel movement has to be powered by a rechargeable battery-operated d. c. drive. For the fine control of the inclination movement the drive is equipped with a speed control which can of course be adjusted from the operating switch.

The vacuum generation occurs via a separate accumulator vacuum unit. This concept enables a quick adaption to new application conditions and also a usage of the vacuum unit for other cases of application. This modular construction allows also a quick replacement / exchange of the vacuum unit, for example in the case that, from the site inspection, a redundant vacuum system is requires. This is via a quick retrofitting possible at any time.

A redundant vacuum system (2-circuit vacuum system) increases the devices safety in the case that one vacuum circuit is not airtight. In this case the other vacuum circuit could still hold the rated load safely. Each vacuum circuit has its own control vacuum meter and vacuum observation. Via an optical and acoustic warning means, in case of a power failure in one vacuum circuit, a warning is given to the operating staff.

Besides smooth elements it is also possible to transport, with an additional structural component, curved facade elements with the vacuum lifting device Balance from us.

Due to the fine adjustment of the inclination angle with the movable counterweight, the work was essentially simplified, the safety risk minimized and the glazing accomplished very quickly.

Add new comment