Photo source

Horn Glass Industries

Date: 23 September 2024

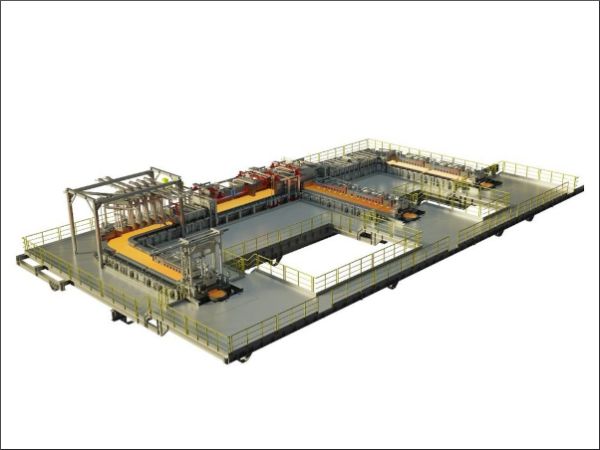

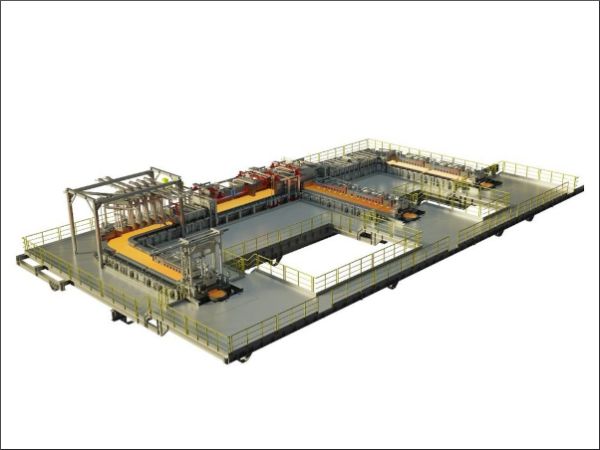

HORN´s latest forehearth system is characterized by the most advanced technology in forehearth design for high-pull forehearths and the highest temperature homogeneity (THI) requirements, e.g. NNPB production.

The HORN glass conditioning system GCS® 301-advanced contains a specially designed cover block with direct & indirect centerline cooling. This cover block allows to separate areas along the control zones into two boundary areas to heat the glass and a central section to guide direct cooling air. The GCS® 301-advanced offers high flexibility with its left/right heating system and uses high-performance insulating refractories for powerful glass conditioning.

DESIGN

- The GCS® Series 301-advanced design allows a wide range of gob temperatures to produce a variety of different sized articles

- Special cover block design for area separation along the control zones:

- Separated boundary areas to heat the glass particularly at the sides of the forehearth

- Separated central section to guide direct cooling air

- Improved thermal homogeneity through optimized transition between equalizing zone and spout

- Superstructure design with direct & indirect centerline cooling

- Use of high-performance insulating refractories

- Powerful glass conditioning

FEATURES

- High thermal homogeneity (THI) for flint glass and colored glass (incl. HORN forehearth boosting)

- Refractory can be designed for additional HORN equipment like: Stirrers, VARI-DRAIN® or forehearth boosting

- High flexibility

- Wide range of production processes

Further informations at https://www.hornglass.com/products/glass-conditioning-systems/forehearth-gcs-series-301-advanced

600450

600450

Horn Glass Industries

2024-09-23T08:00:00

Horn Glass Industries: Forehearth GCS® Series 301-Advanced

glassonweb.com

Add new comment