Date: 3 September 2015

Delegates to the company’s specialist safety workshop in Lyon this May were informed about successful trials of the Heye Swabbing Robot at a high speed, high performance plant in the Netherlands, where the equipment is now in permanent operation, making NNPB ware.Benefits observed by the customer include zero rejects from swabbing, the avoidance of section stops, a 75% saving on lubrication and improved operator safety. Stable and repeatable volume, thickness and location of swabbing agent in the process have been realised, with more time for operators to focus on production optimisation and defect correction. Two versions of the swabbing robot are installed at the same site, emphasising Heye’s continuing focus on the realisation of further improvements. The latest version features a cycle time of just one second and lower total weight (25kg) than the previous one. In addition, the zero station is smaller at 1150mm, more parking positions have been provided and a smaller safety cage has been created.

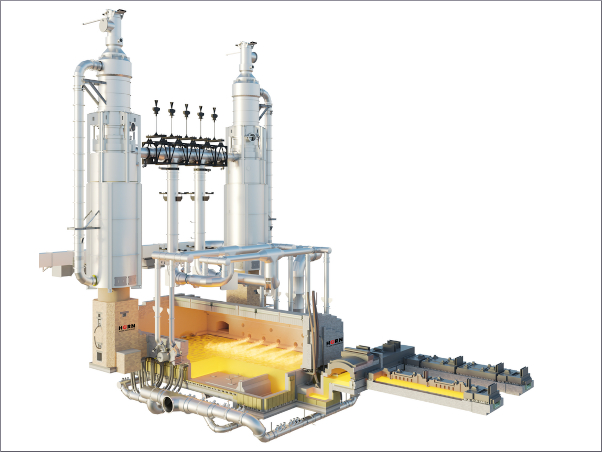

The Swabbing Robot is the latest in a series of equipment developments from Heye International, aimed at optimising the glass container production process. In combination with the company’s Multilevel Safety Concept, the SpeedLine IS machine offers different options to increase work safety, as well as providing higher product quality. A second example of the company’s ongoing development program involves its approach to IS machine lubrication. The Speedline IS machine has an integrated (optional), temperature-guided lubrication system, using 70% less lubricating oil. Annual cost saving of €70,000 have been calculated, based on two furnaces (80 sections) and the use of 6000 litres instead of 20,000 litres of machine lubricating oil.

Add new comment