This paper was first presented at GPD 2023.

Link to the full GPD 2023 conference book: https://www.gpd.fi/GPD2023_proceedings_book/

Authors:

- H. Alkisaei (1),

- Y. Maachi (2),

- C. Justino de Lima (2),

- C. Noteboom (1, 3),

- C. Louter (1)

(1) Delft University of Technology, Faculty of Civil Engineering and Geosciences, Delft, The Netherlands

(2) American Glass Research, Delft, The Netherlands

(3) Van de Laar, Eindhoven, The Netherlands

Container glass is omnipresent and reuse can be observed all around the world. It can even be reused for the construction of structural components for buildings of which several examples exist around the world. However, research on the reuse of glass for structural components seems lacking. Therefore, this paper investigates the potential of reusing glass bottles for the construction of structural columns. Firstly, the compression strength of artificially abraded glass bottles was investigated in compression tests, revealing a compression strength between 10 and 20 kN. Secondly, alternative assemblies of multiple glass bottles were tested in compression, to determine their suitability for constructing a column. Finally, an exemplary column prototype constructed of glass bottles is presented. From the findings, it is concluded that it is feasible to reuse glass bottles for the construction of structural columns that could carry small-scale structures.

1. Introduction

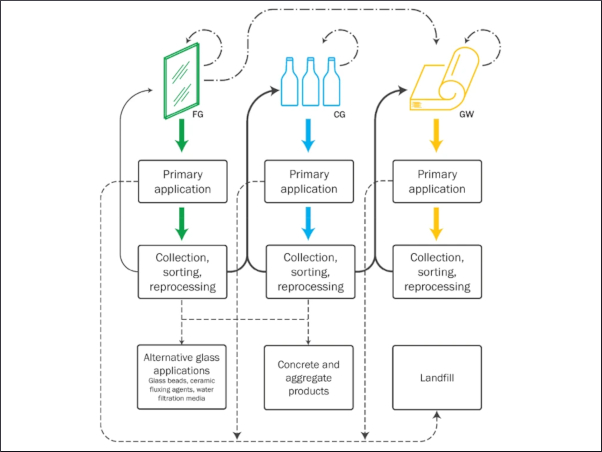

The percentage of glass container production of the total glass production seems to be decreasing slightly, however, glass container production is still growing (FEVE, 2018). Harder (2018) states that the worldwide recycling rate is about 32% for container glass. This is firstly due to the fact that in developing countries the recycling industry is very informal (Liebenberg, 2007). And secondly due to that the market for recycling is very limited in, for instance, Africa.

Besides recycling glass bottles, the reuse of glass bottles is also an option. However, returning used bottles back to the fillers is rather difficult due to the widespread production and distribution of these glass bottles (Dyer, 2014). Citizens of relatively more remote areas or developing countries, who produce glass waste, have even less access to this option. Moreover, melting the cullet back into new products costs energy. Finding a second life for glass waste, such as being a building material, is therefore beneficial.

Individuals and communities in developing countries have been building shelters and homes that are made out of beer or wine bottles. These are usually mixed with cement mixtures in order to create solid-like structural elements.

One of the most famous examples is Wat Pa Maha Chedi Kaew in Thailand. The bottles were used as construction materials in combination with concrete and are placed both horizontally and vertically. The inside of the temple contains load-bearing columns, floors and walls made out of glass bottles.

Also in The Bottle Houses in Wellington, Canada (Lecacheur, 2020), cement was used to bind the bottles together to create load-bearing elements (Rom, 2015).

In 2014 Eli Hansen and Oscar Tuazon created an esthetical column out of glass bottles without the use of concrete or cement, which was used in several art galleries.

In the 1960s, the owner of Heineken initiated the idea to create a bottle that could also be used as a building block: the WOBO-Bottle.

However, concerns on the marketing side eventually led to the abandoning of the project (Sieffert, 2014), (Bridgens, 2018). Besides the aforementioned examples, several other projects involving the structural use of glass bottles exist around the world.

However, research on the reuse of glass bottles as a structural material seems lacking. Therefore, this paper explores the potential of using glass bottles as a building material. More specifically, it investigates the compressive strength of glass beer bottles, proposes alternative stacking configurations for creating structural columns using beer bottles and investigates the compression strength of four selected stacking configurations. Finally, a design of a structural glass column made of stacked beer bottles is presented. The findings presented in this paper are based on an MSc thesis executed at TU Delft (Maachi, 2022).

2. Strength test methods & results

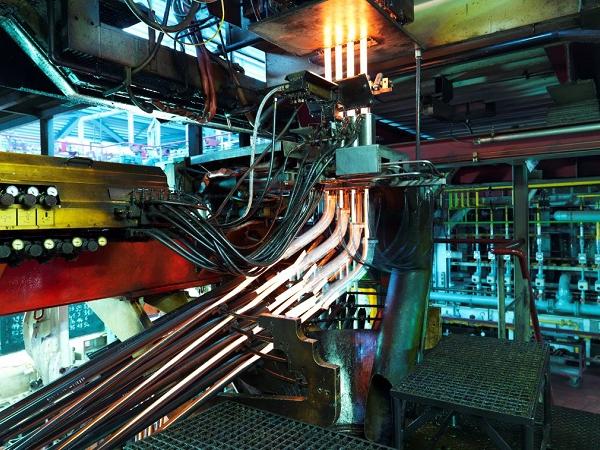

Müller-Simon et al (1994) state that the strength of container glass is not solely dependent on the stress distribution inside the container. The coatings, imperfections, flaws, and inhomogeneities all play a key role in the strength of container glass. MüllerSimon et al (1994) found that each type of defect has its own individual distribution on a glass bottle. It is important to understand the possible defects that can originate during the manufacturing process or subsequent handling of glass bottles. Aldinger & de Haan (2019) have summarised the defects in a glass bottle, which can either cause stress-increasing or strength-reducing effects. In addition, a relatively straightforward finite element model showed that under a vertical compressive load, tensile stresses will occur in and around the shoulder and heel region in both longitudinal and circumferential directions. This was also discussed by Southwick (1965).

Compression strength tests on single glass bottles

To design structures with container glass, and more specifically columns made out of glass beer bottles, characteristic strength values have to be retrieved. The characteristic strength of the beer bottles, loaded along their vertical axis, has been evaluated through destructive compression tests performed at AGR in Delft. The bottles were purposely damaged before the destructive testing to resemble both the damage from a beverage factory with a line-simulator and the damage due to handling with manual abrading. The bottles that were used for the tests were 330 ml longneck beer bottles. Per series (i.e. line-simulated or manually abraded) a total of twenty-eight bottles were tested. From the testing, it was observed that the line-simulated specimens reach an average compressive load value of 16.11 kN, whereas the manually abraded specimens reach an average compressive load value of 17.30 kN. Furthermore, it was observed that the majority of the line-simulated and manually abraded specimens fractured at the shoulder contact region.

By means of Weibull analysis and FE-analysis, it was determined that the line-simulated specimens show a characteristic tensile strength of about 27 MPa, whereas this amounts to 20 MPa for the manually abraded specimens, taking their respective fracture locations into account.

Compression strength tests on assemblies of glass bottles

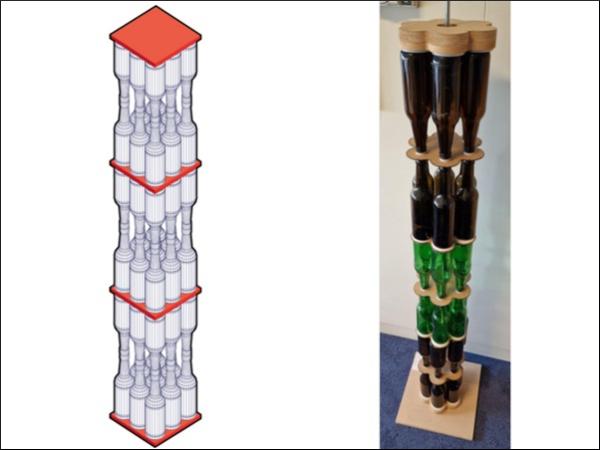

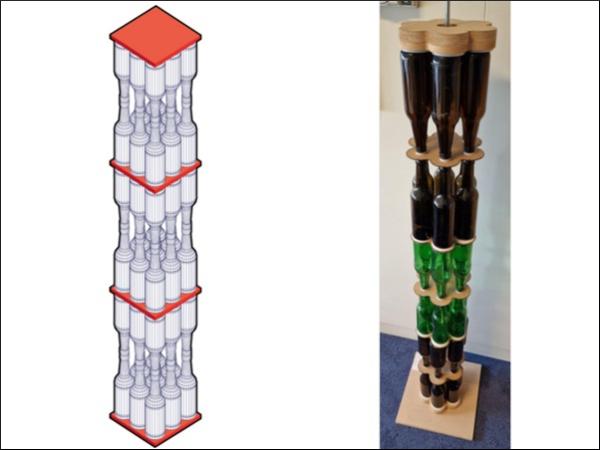

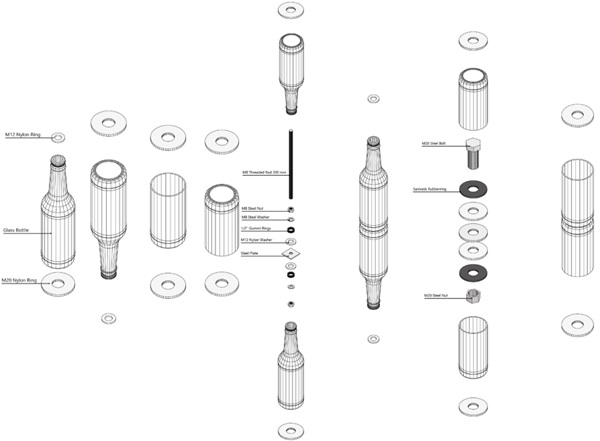

Basically, glass bottles are designed such that they are able to withstand vertical loads due to the self-weight of stacked bottles from above, such as in warehouses. These bottles either rest on pallets or special pads. Based on this stacking principle, eight alternative stacking configurations were designed to connect glass bottles within a structural glass column, see Figure 1. For configurations C1, C2, C5 and C6 the bottles were kept whole, whereas for configurations C3, C4, C7 and C8 the bottles were cut at the shoulder. For configuration C5 a metal rod was placed in order to keep the two stacked bottles in place. For configuration C6 the bottom parts are glued to each other. For all configurations nylon and aluminium rings were in place for load transfer.

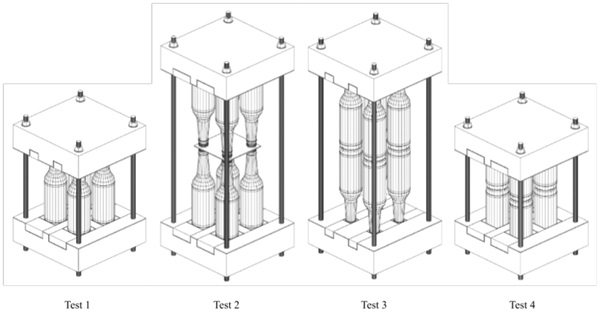

From these alternatives, four configurations (C1, C5, C6 and C8, see Figure 1) were selected for further strength testing, see Figure 2. These configurations were each tested in an assembly of 4 bottles with a wooden plate on either side of the bottles, see Figure 2 and Figure 3. Such assembly of 4 bottles with wooden plates are foreseen to act as a segment within a larger structural glass column construction, see Figure 5.

As such, the following tests were executed, see also Figure 2:

- Test 1: 4 compression tests on an assembly of single bottles between wooden plates (C1)

- Test 2: 4 compression tests on an assembly of stacked bottles connected finish-to-finish between wooden plates (C5)

- Test 3: 4 compression tests on an assembly of stacked bottles connected bottom-to-bottom between wooden plates (C6)

- Test 4: 3 compression tests on an assembly of bottles cut at the shoulder and stacked and connected bottom-to-bottom between wooden plates. (C8)

The machine that was used for the compression tests is a hydraulic displacement-controlled compression machine by Schenck. The displacement rate was equal to 0.005 mm/s. The bottles were surrounded by transparent tape, so that it was possible to inspect the bottles after failure and to prevent an explosive failure as much as possible.

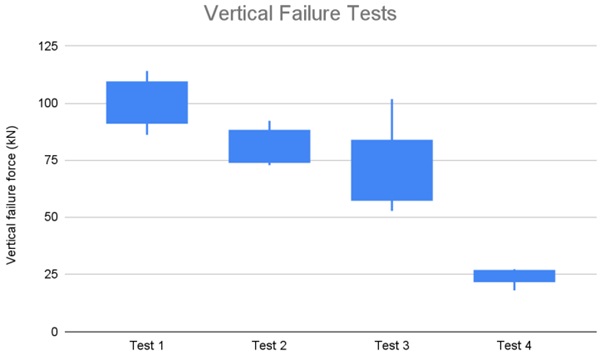

The results of the tests show the vertical force recorded by the machine.

Test 1 reached the highest failure loads. This could be due to the fact that the other tests have a larger chance of weak governing flaws and different force flows. However, Test 2 and Test 3 can create a much larger height and need less plate material. Test 4 offers no competitive results due to the imperfections at the cut surface, which initiated premature fracture.

Column Design

The choice of the desired glass bottle pattern mainly depends on the necessary capacity of the column i.e. how many bottles are needed to resist the vertical load.

In comparison to conventional materials, like concrete, steel or timber, it can be shown with hand calculations that the design compression load of a column with glass bottles is much lower.

Further limitations of columns made out of glass bottles are height tolerances, the variability in bottle designs, bottle patterns, connection costs, post-breakage behaviour and safety.

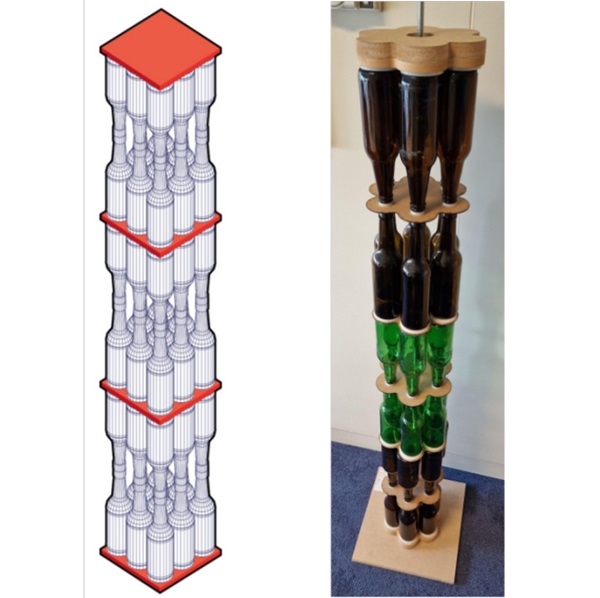

Figure 5 presents a conceptual design and a prototype of a column made out of glass bottles. The prototype consists of 6 bottles per layer, a steel tension rod in the middle in order to keep all the layers and bottles intact and nylon and aluminium rings at the top/bottom of each bottle to transfer loads. Each layer is separated by a wooden plate.

3. Discussions and conclusions

Experiments and FEM modelling have shown that under vertical compression load rings of tensile principal stress form in the shoulder and heel of a glass bottle. These locations are also where failure occurs.

The characteristic strength of the container glass was retrieved by means of a Weibull Analysis. It was concluded that abraded container glass has a characteristic tensile strength of about 20 MPa, whilst linesimulated container glass has a characteristic tensile strength of about 27 MPa.

It was observed that the thickness of the tensile stressed areas has a significant effect on the failure load.

Eight configurations were developed for stacking glass bottles to form a structural glass column. Four selected configurations were analysed at the laboratory. Test 1 behaved best under vertical loads with a minimum failure load of 86.05 kN. Test 2, Test 3 and Test 4 had a failure load of 72.75 kN, 52.67 kN and 28 kN respectively. The differences in failure loads are due to the amount of connection points and imperfections.

A column made of glass bottles is currently limited to temporary or small projects. These columns should be designed with a damaged state of the bottle with a characteristic tensile strength of 20 MPa. The load-duration effect on glass and a tolerance factor due to the proposed connections should also be taken into account.

Acknowledgements

The completion of this research project would not have been possible without the contributions and support of AGR in Delft and The Stevin Lab at the TU Delft.

References

Aldinger, B. S., & de Haan, P. W. (2019). Color Atlas of Glass Container Defects. Blurb, Incorporated.

Bridgens, B (2018). Creative upcycling: Reconnecting people, materials and place through making. Journal of Cleaner Production 189, 145-154.

Dyer, T. D. (2014). Glass Recycling. Handbook of Recycling, 191–209. https://doi.org/10.1016/b978-0-12-396459-5.00014-3

FEVE. (2018). Food and beverage market growth for glass packaging. Glass Worldwide, 80, 114. https://www.glassworldwide.co.uk/Digital-Issues/glassworldwide-issue-80

Harder, J. (2018). Glass recycling - Current market trends. Recovery, 5. https://www.recovery-worldwide.com/en/artikel/glass-recycling-current-markettrends_3248774.html

Liebenberg, C. J. (2007, October 1). Waste Recycling in Developing Countries in Africa: Barriers to Improving Reclamation Rates [Paper]. In Eleventh International Waste Management and Landfill Symposium. CISA. http://www.resol.com.br/textos/136.pdf

Lecacheur, J. (2020, July 12). Les maisons de bouteilles, à Cap-Egmont, fascinent toujours, 40 ans plus tard. Radio-Canada.Ca. Retrieved October 17, 2022, from https://ici.radio-canada.ca/nouvelle/1719102/maison-bouteilles-cap-egmontile-prince-edouard-visite

Maachi, Y. (2022, December 2). Exploring the potential reuse of glass bottles in structural columns. https://repository.tudelft.nl/islandora/object/uuid%3Aeb8529e3-b118-46c1-bc4b-350bf286eb38?collection=education

Müller-Simon, H., Jorg, W., & Armin, L. (1994). Practical strength of glass containers Part 1. Influence of the type of defect. Glastechnische Berichte, 67(5), 134–142.

Rom, J. (2015, May 22). Bottle Houses of PEI. Upcycle That. Retrieved October 17, 2022, from https://www.upcyclethat.com/bottle-houses-of-pei/

Sieffert (2014). Sustainable construction with repurposed materials in the context of a civil engineering-architecture collaboration. Journal of Cleaner Production 67, 125-138.

Southwick, R. D. (1965, May). Pressure and Vertical Load Stress Indices in the Handy Beer Bottle (No. 65–027). AGR.