Date: 27 August 2025

At VITRUM 2025, Glaston presents a comprehensive range of smart technologies and integrated solutions that redefine glass processing across tempering, laminating, insulating, and mobility glass sectors. The focus is on automation, energy efficiency, and superior product quality.

Glass Tempering

The new Glaston FC Series E tempering line combines flexibility and energy efficiency with the Glaston Bora convection system for precise heating. It supports all glass types and features advanced automation for consistent, high-quality output. The Roller Heat Control (RHC) ensures uniform roller temperatures, reducing defects and energy use.

Other latest advancements in Glaston tempering technology include:

- Autopilot: The only fully automated solution for mixed production, adjusting heating and cooling based on glass type, size, and load to boost efficiency and eliminate operator dependency.

- Online Stress Calculation: Real-time, data-driven monitoring of hardening results for consistent quality and enhanced safety.

- Glass Temperature Imaging: Ensures accurate Low-E glass temperature control for energy-efficient production without compromising quality.

- Anisotropy Control: Lowers anisotropy levels by up to 50% using advanced airflow and heating control.

- Adaptive Quench: Automatically adjusts cooling zones to match glass load length, reducing energy use and carbon footprint while maintaining productivity.

All the above features are also available as upgrades!

Glass Laminating

Glaston ProL lamination technology offers flexibility for mixed production with a convection heating chamber that simplifies switching between glass types. The new ProL SPEED edition increases efficiency by up to 40% with full automation for handling, foil placement, and trimming. The patented ProL Convection Control enhances output with structural laminates like SentryGlas®, while the ProL-zone upgrade replaces infrared heating with convection, reducing energy consumption by at least 50%.

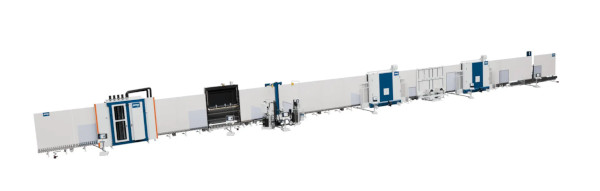

Insulating Glass Manufacturing

Glaston ULTRA TPS® introduces a patented method for producing thin triple IGUs, with center glass as thin as 0.5 mm. These units match the thickness of standard double IGUs but offer superior thermal performance, ideal for both new builds and retrofits. They also improve light transmission and reduce material use. The line also efficiently produces quadruple IGUs with thin glass.

Glaston MUNTIN’MASTER automates muntin placement, eliminating manual steps and increasing precision and cost-efficiency.

Mobility Glass Processing

Glaston CHAMP EVO is the latest in pre-processing for mobility glass, offering high precision, energy-efficient drives, and faster changeovers. Glaston MATRIX EVO, an automatic bending furnace, delivers top optical quality for complex automotive glass applications like ADAS and HUD. Its modular design and active convection system enhance energy efficiency. The line is especially effective for processing borosilicate glass – a more durable and lightweight alternative to traditional soda-lime glass.

Automation and Upgrades

Glaston Batch Optimization uses robotics to create the most efficient batch patterns, maximizing furnace bed use and production capacity. Glaston’s automation solutions integrate mechanical systems with process intelligence, ensuring every step in the workflow is optimized.

To support long-term performance, Glaston also offers a comprehensive portfolio of upgrades and lifecycle services. These help you maintain equipment efficiency, extend machinery lifetime and ensure your production stays up to date and meets or even exceeds industry standards.

Come meet with our industry experts at Booth #D13 E12 in Hall 9. We can tell you more!

Visit the Event page: Glaston at VITRUM 2025

600450

600450

Really impressive innovations from Glaston — the focus on automation and energy efficiency is exactly what the industry needs right now. I like how the new tempering and laminating technologies don’t just cut costs but also reduce environmental impact. It reminds me of other industries, like houston pool cleaning services, where efficiency upgrades and smart systems have completely changed how work gets done. Excited to see these solutions showcased at VITRUM 2025!