Date: 30 July 2015

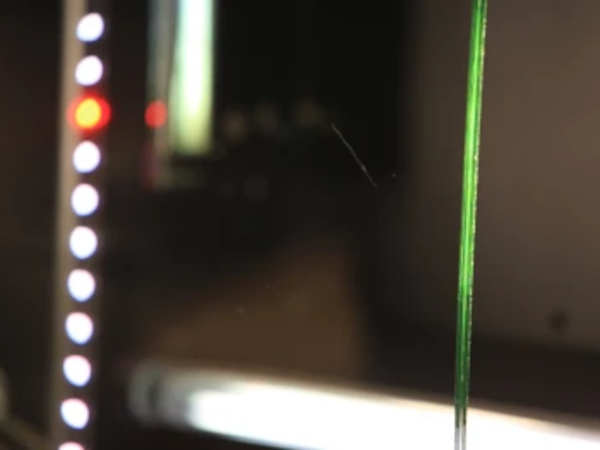

EMC has a solid experience in the field of hollow glass quality inspection machines.In less than ten years, EMC is working with companies like Verallia group, O-I group, Vidrala Group and Vetropack group. EMC develops inspection machines with commercial parts at reasonable prices and according to clients’ procedures. www.electromanteniments.comEMC has installed a Semi–Automatic Impact tester in the coca-cola laboratories located in Brussels; Coca-cola has improved their former manual system with a EMC's system.

EMC has a solid experience in the field of hollow glass quality inspection machines.

In less than ten years, EMC is working with companies like Verallia group, O-I group, Vidrala Group and Vetropack group. EMC develops inspection machines with commercial parts at reasonable prices and according to clients’ procedures.

www.electromanteniments.com

Add new comment