Date: 13 March 2012

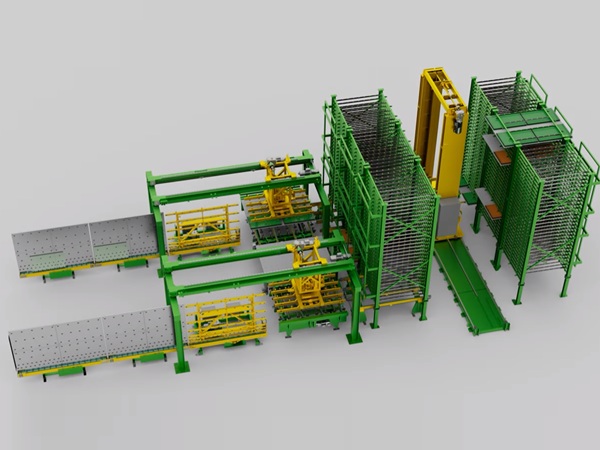

After extensive negotiations the two companies have forged a strong alliance in developing a state-of-the-art facility that will supply the highest quality products to the market. For The Glass Machinery Company team, headed up by Phil Birchall, the project was carefully tailored to meet the needs of a growing business. Meticulous attention to detail was incorporated into the CAD/CAM design for the 15,000 sq. ft facility to ensure that the new equipment would cater for the current and future production needs of Cornwall Glass and Glazing. This is the latest branch to be opened by Cornwall Glass at Highbridge, (Nr Bristol) in Somerset which now makes 13 sites in total within the Southwest region.

The company employs nearly 200 staff and it is expected that the new facility should boost group production by approaching 25% in the next 18 - 24 months. Cornwall Glass has over 30 years experience in the glass processing industry, in which time the company has established a reputation for quality and reliability. There has been steady but substantial growth over the years with the broad product range now including sealed units, mirrors and toughened glass. As the reputation of the company continues to grow and with orders steadily increasing it was imperative when making the investment decision, to order equipment that would not only substantiate the existing standards but that would help to further enhance the company’s reputation in difficult economic times. As with all ‘works in progress’ the challenges for The Glass Machinery Company came as the project altered to accommodate an evolving corporate plan. Cornwall Glass already has extensive glass processing facilities, which customers in and around the local region have come to rely upon.

The company is recognized for its craftsmanship and experience across a broad section of industry areas and can offer services such as cutting, drilling, polishing and shaping products to individual customers’ requirements. Additionally Cornwall Glass can heat soak test toughened glass and can offer a full glazing service to both domestic and commercial customers alike. With this in mind The Glass Machinery Company team evaluated the production floor and started to develop design ideas that would help to improve productivity and efficiency, in essence to help take the business further forward as it initiates this expansion programme Mark Mitchell, Managing Director at Cornwall Glass and Glazing comments, “We strive to produce the highest quality products and manufacture our own EN 1279 compliant double glazed sealed units and EN 12150 compliant toughened glass. As a company with a forward thinking approach we aim to continually evaluate and improve Cornwall Glass and Glazing as a business in order to maintain our high standards.

The Glass Machinery Company has offered a novel, no-nonsense approach which has greatly helped us to initiate our development programme effectively” With branches spread across the South West region, Cornwall Glass and Glazing has to ensure that the production capacity can accommodate increasing customer orders at all the sites. The company prides itself on offering one of the broadest ranges of glass and mirror products which are available from stock. Additionally the company installs a vast range of glass, mirror and glazing products, which all comply with the latest industry building and safety regulations. These are used for all types of commercial projects such as warehouses, factories and retail properties to bars, hotels, restaurants and tourist attractions. As the expansion programme changed, The Glass Machinery Team has accommodated the alterations and modified the CAD/CAM design accordingly.

During the planning stages, frequent site visits and the ability to adapt quickly demonstrated a proactive approach to building business relations for senior management at Cornwall Glass. Mark Mitchell comments, “The Glass Machinery Company were very attentive, good listeners who ultimately achieved a demanding package within a set budget. They offered a flexible solution with good humour and patience along the way!” He continues, “Nothing to date has been too much trouble or hassle, and The Glass Machinery Company has been fantastic, providing solutions all the way regarding numerous imposed restrictions that were mainly due to space. Friendly, honest and refreshingly open in all discussions, it made a refreshing change to talk to a company who did not knock the competition along the way which is a real breath of fresh air! “ The company estimates that the new installation will yield a considerable productivity increase over the coming 12 months. The new installation will also increase the opportunity for the research and development team at Cornwall Glass and Glazing to grow the portfolio and could potentially help to further boost the local economy. Mark Mitchell comments, “ The CAD/CAM designs were invaluable as they ensured our new machinery will fit well within our premises and Phil pitched the company’s offering in a very diligent, tempting manner. Phil Birchall has a genuine desire to develop long term trading relations and this approach has fostered a trusting relationship from day one. He concludes, “The Glass Machinery Company team knows that our company is a loyal and progressive, major regional player and we enjoy fostering business relations with those who have similar working ethics to our own. This has resulted in us deciding to negotiate additional orders with them.” Phil Birchall, Managing Director at The Glass Machinery Company comments, “It is very rewarding to know that the products and customer care services we offer have been recognized so positively. Cornwall Glass has given us a great platform to demonstrate our skills and experience. It is equally positive to know that with the state-of-the-art equipment that Cornwall Glass can focus on further growth and positive results.”

Add new comment