Date: 24 January 2008

At an unbelievable 13.30 x 3.10 meters, Sedak is producing what is probably the largest glass lites in the world at this time, from laminated safety glass. But production is one matter and handling the glass is another. Until recently, there were still not any vacuum suction pads capable of working with lites of this dimension.

The main specialty of Sedak GmbH & Co. KG, which belongs to the Seele Group, is laminated glass with high-quality design. In addition to glass/glass and glass/metal laminates, the company also processes photo sheets and extremely small laminates as small as 50 x 50 mm.

Recently Sedak GmbH & Co. KG was commissioned to produce lites with record dimensions of 13.30 x 3.10 metres for the external façade of an internationally renowned company. Laminating these lites presented no problem, but until that time Sedak had no handling equipment capable of moving the heavy lites, which weigh several tons, reliably and precisely.

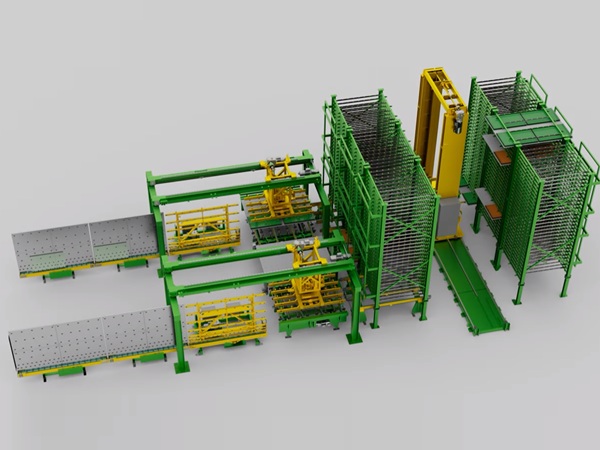

For this reason, an order was placed with the Bystronic glass Technology Center in Armatec for the world’s largest handling device ever to be built. The company with headquarters in Gunzenhausen is considered the indisputable expert in constructing handling equipment and has also made a name for itself in the past producing production lines for laminated safety glass, crane systems, and special machines. The Glasmaxilift 5000 – able to handle lites up to 15 meters in length and 5 metric tons with no problem

The Glasmaxilift 5000 – able to handle lites up to 15 meters in length and 5 metric tons with no problem

The ultimate result was a true giant among vacuum lifters, the Glasmaxilift 5000. The device itself tips the scale at 2.5 metric tons and is capable of moving lites up to 15 meters in length and 5 metric tons in weight. With a total of 54 suction plates, the Glasmaxilift 5000 can safely handle loads and tilt them up to 90 degrees, controlled by several lift spindle drives. Each suction pad is fitted with its own control pressure gauge and can be separately shut off. To release the glass plate after transport, a countercurrent of air is directed at the suction pads. The operator’s safety is ensured with three independent safety circuits.

The Glasmaxilift 5000 was not delivered to Sedak until a successful fire test was completed – an extensive test under realistic conditions at the Armatec Vierhaus GmbH facilities, where the unit has now been in use successfully for some time.

Armatec Glasmaxilift 5000 claim to the title of “largest handling device in the world” will probably be short-lived, since it is only a matter of time until the market demands even larger lites.

Add new comment