Date: 16 September 2015

The production of O-I is focused on glass containers for beer, wine, distillery products, foods and drinks.In Italy it has 11 factories, employing 1,800 employees and from which every day are shipped standard and customized bottles to the main players of the Italian "food & beverage" market, including companies such as San Pellegrino, Fratelli Carli, Monini, Ponti, Caviro and Nosio.Some of these have also become testimonial of the campaign "Glass is Life" aimed to demonstrate the unique qualities of glass packaging and its ability to create successful brands in the food and beverage industry, showing the love consumers have for this type of material.

.jpg)

Aerial view of O-I Manufacturing plant in Origgio

Glass is a 100% natural material; the raw materials from which it is composed include sand and limestone. It can be used and recycled over and over again. But not for this reason its production is totally painless for the environment: the high melting temperatures of its components may in fact lead to the formation of nitrogen oxides (NOx), which besides being a greenhouse gas, are also one of the main causes of acid rain.

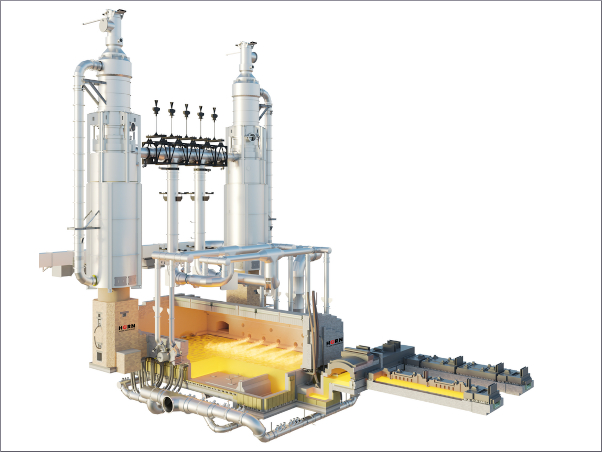

O-I, once again, proved to be a company that stands out for the strong environment respect, deciding to equip its plant in Origgio of a catalytic system (SCR) for the nitrogen oxides removal. Such a system, the first in Italy regarding container glass, involves the injection of ammonia solution inside the duct at the outlet of the ESP. The ammonia will react then with the nitrogen oxides present in the flue gases on the surface of a catalyst, transforming them into nitrogen and water and allowing the release of those harmless compounds into the atmosphere.

.jpg)

View of the stack of O-I Manufacturing plant in Origgio

ATS intervention will then be focused to the integration of such a system in the existing flue gas treatment plant, by limiting as much as possible the unavailability of the desulfurization unit and ensuring, through appropriate modifications, that the plant, in its final configuration, has no impact on depression maintained nowadays, indeed ensures a better stability even during the phases of reversals typical of a melting furnace for glass.

Add new comment