Date: 16 May 2014

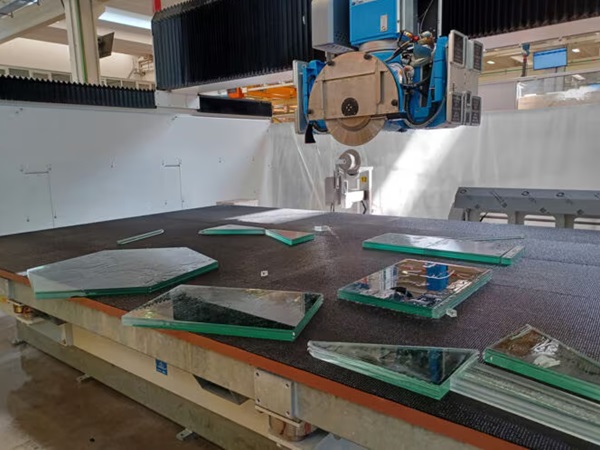

We manufacture and export all over the world a wide range of machines for shaped glass processing, which starts from the simple semiautomatic machines up to the most sophisticated CNC.Our machines are specifically designed to meet the stringent requirements of heavy production with superior performance and minimal maintenance.

Lovati F.lli: 75 years of experience and continuous innovation!

Journey Through Time

1939 Lovati F.lli is established in Milan, Italy

1963 We produce our 1st glass working machine

1968 Mr Angelo Lovati, current President, joins the Company

1970 We produce our 1st fully automatic electromechanical machine for glass

1973 Mrs Lory Lovati, current Sales Manager, joins the Company

1975 We produce our 1st fully automatic electronic machine for glass

1979 We produce our 1st CNC and open our new plant in Assago

1980 We install our 1st machine in the USA

1983 We go to Asia, installing our machines in Indonesia

1984 We go to China with our machines and we produce our 1st numerical control loading unit

1990 Our America branch opens in North Carolina, USA

1996 We produce our 1st CNC with multiple heads

2003 We start to produce our special CNC “Bem” and Mrs Corinna Lovati, current Export Manager, joins the Company

2010 We increase our production range with the new drilling our routing machine “Alcor100”

2012 We start to produce our new engraving CNC “Groove”

2014 We proudly celebrate our 75th anniversary!

And the story goes on…

Our Production Range

- 3 & 4 axis CNC (Bem, Concept and Izar Series)

- 3 axis CNC with multiple heads (Lov622-2ts)

- 5 axis CNC (Zephyr and Giant Series)

- CNC for corners (Lov07 and Twin07)

- Engraving CNC (Groove Series)

- Drilling and routing CNC (Alcor100)

- Automatic drilling machine (Rigel120)

- Loading & unloading units (Cal / Scal Series)

- Fully automatic edging, bevelling and polishing machines with template

- Semiautomatic edging. bevelling and polishing machines (Lov1000 Series)

- Manual edging machine (Lov01m)

- Rebuilt machines

- Custom-built machines & lines

Add new comment