Latest articles

| In this ninth episode of #AskGlaston flat tempering series, we explore how to optimize energy efficiency in the case of short loadings.

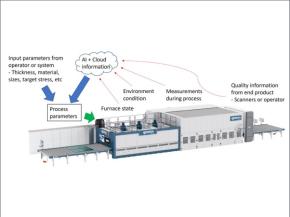

| In the seventh episode of the #AskGlaston flat tempering series, the focus is on the Tempering Autopilot.

| As labor shortages and efficiency demands grow, automation is transforming glass tempering—starting with AI-driven batch building that boosts productivity, cuts energy use, and maximizes furnace performance.

| Modern tempering technologies offer impressive energy efficiencies for glass processors. But, have you ever come across energy-saving claims that seem too good to be true?

| Glass tempering is a process that can be made in many ways to get tempered glass that meets the standards. The selected way is usually chosen by the operator and is almost always based on experience instead of science.

| In the latest Glastory blog post, Antti Aronen analyzes the transformative potential of automated glass tempering.

| In this third episode of the #AskGlaston flat tempering series, Taneli Ylinen deals with the commonly asked question of how to handle the issues with mixed production.

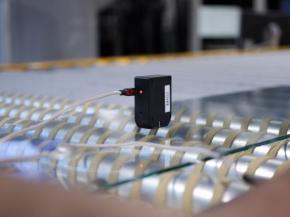

| In the second episode of #AskGlaston Flat Tempering Series, we will talk about the new solution to estimate the stress level in glass – online.

| This latest Glastory blog by Miika Äppelqvist is dealing with the areas of the tempering process that can be improved to make operations more efficient.

| In glass tempering, we look for equipment that uses less energy, leading to fewer emissions. But sometimes, the numbers are too good to be true.

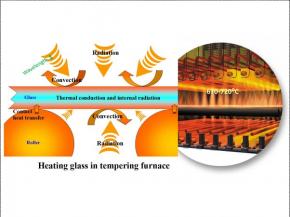

| Global environmental concern is motivating efforts to improve energy efficiency in all industrial sectors. And glass tempering is no exception.

| Glass production is an energy-intensive process by its nature, so even small reductions there can result in considerable savings in energy and costs.

| Full convection, forced convection, focused convection, recirculated convection – the list of terms goes on and on.

| Glaston is working hard to make tempering furnaces more automated.

| In this paper, the basics of the heat flux modes are given, a solution method for the glass energy equation is introduced, and some tempering furnaces are theoretically studied to show the portions of the heat transfer phenomena inside furnaces…

What do power consumption, installed power and installed capacity of a glass tempering furnace mean?

| Power consumption of the glass tempering furnace refers to the amount of electric energy consumed in the process of tempering certain quantity of glass. The measuring unit commonly used is the kilowatt hour (KWh).

| We’ll help you meet the spec with our knowledge of the glass tempering process.

| Glass makes modern life possible, from our coffee makers, fireplaces, and induction cooktops to oil pipelines, syringes, lasers, and more.

| Skaala was founded in 1956 as a one-man company. The father of the two current owners, Hannu and Markku Hautanen, was a carpenter and already in those days, he processed glass while repairing doors and windows.

| In August 2013, the LiSEC development team started a major project with the mission: redesign of the tempering furnaces in order to save manufacturing costs and at the same time increase the process reliability. Result: the AEROFLAT.

![Tempered Glass Specifications [Video & Transcript] Tempered Glass Specifications [Video & Transcript]](/sites/default/files/styles/30_290_x_186_/public/articles/2017/HHH-Tempering.jpg?itok=3-N69e1G)