Date: 24 September 2013

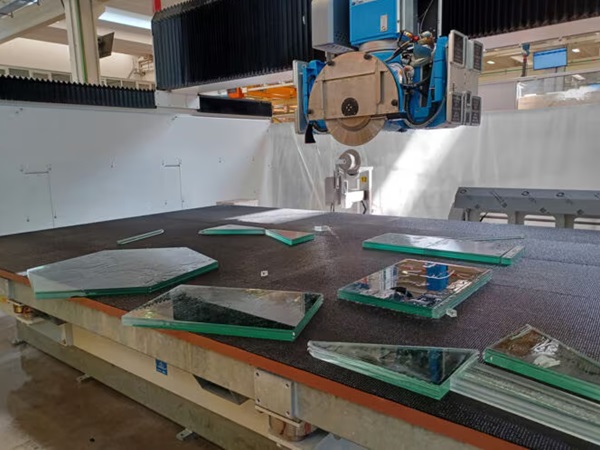

The products of the Quick series are meant for a market segment where a fully automatic CNC center is neither necessary nor economically feasible, but where accuracy and speed are essential criteria.

QuickDrill, the drilling machine, makes drilling holes and countersinks over the entire working area, with no black zones.

QuickMill is a true micro-center performing cuts and notches with speed and precision.

Both are equipped with a powerful numerical control with touch screen, which allows a complete and easy programming of all functions, automatic management of the spindle, and the storage of work programs.

These machines can work as stand-alone modules or can be put in line for increased productivity thanks to the two separate processing steps executed simultaneously.

They will be displayed on the stand at Vitrum, in line with a washing machine LV Top, proving once again how Neptun is always oriented to innovate the world of glass with solutions designed for ease of use, durability and - last but not least - high quality.

For those who require complete automation, also Drillmax will be exhibited, which represents the high range of CNC vertical Neptun. Drillmax is the only center with two drilling heads and a dedicated milling head.

At the same booth, you will also see the edging machines Rock 11 with the squaring system Edge to Shape, which now also provides the ability to manage the out-of-square, in addition to squaring at 90 ° and the accurate sizing of the glass sheets, and Rock 10-45, the new mitering machine with 10 wheels, which just like the other models of the Rock, is characterized by the unusual blend of traditional strength and revolutionary technology that ensures the absolute processing quality typical of Neptun’s edgers.

Finally, we present the new version of the washing machine Tornado HP 1664, made completely in high quality stainless steel, both in the washing and in the drying section.

Your visit to the stand Neptun, Hall 22P Stand F21/K22, will offer you a new view on glass processing!

Add new comment