Date: 12 November 2001

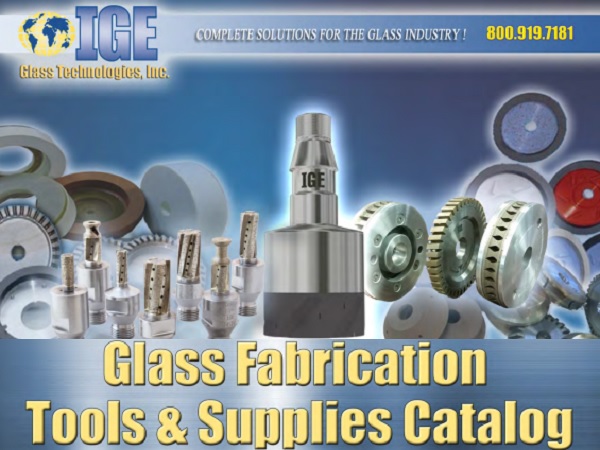

About the company:The Glass Division of the Tyrolit Group designs, produces and internationally distributes metal and resin bonded diamond tools for all the chief types of work on glass: glass for furnishing, for construction, hollow and illumination glass, lead crystal, glass for vehicles, optic glass and for other special applications. Tyrolit Vincent can offer the first manual on machining flat glass: “The Mastery of Flat Glass” is a practical guide which illustrates the technical features of the abrasives and binders in the tools, a manual distributed free of charge by machining flat glass Tyrolit Vincent.

About the company:

The Glass Division of the Tyrolit Group designs, produces and internationally distributes metal and resin bonded diamond tools for all the chief types of work on glass: glass for furnishing, for construction, hollow and illumination glass, lead crystal, glass for vehicles, optic glass and for other special applications.

Add new comment