Latest news

297 results

| The meeting point between Mappi and Somec was an ATS 4.0 tempering furnace.

| A letter of thanks from Germany for the technical upgrading of a SC-1B42 tempering furnace.

| From ashes to flagship FC Series - Custom Glass UK orders Glaston’s FC Series tempering furnace line

| 2020 - Looking back on what we have gone through together

| The upgrades will be delivered and installed in March 2021.

| Glaston Group has closed a deal for a FC Series™ tempering line with one of the largest suppliers of turn key sunrooms in North America.

| A MappiSUPERTEMPER™ tempering furnace achieves the characteristics necessary to certify E30 glass for fire resistance.

| Window Creations choose ATS Mappi tempering furnace.

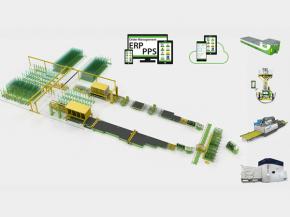

| NorthGlass Tempering Furnace BU exceed 15 million USD sales and 40 orders in both October and November.

| Mappi International has won the 2020 USGlass Readers’Choice Award for Machinery - Tempering Equipment with Industry 4.0 Tempering solutions, now enhanced with “Powered by Siemens” improvements.

| Launching New Zealand’s state-of-the-art facility for advanced insulated glass units

| In October effective tempering furnace orders were 40 and its total amount of nearly 21 million dollars.

| Mappi met Nermin Berbic to talk about his company, and their recent improvement: an all new tempering furnace, a Mappi Fox 1500x3000.

| Today, with the entry into force of an order for a tempering furnace in South Korea, the cumulative sales volume of NorthGlass tempering furnace has exceeded 5000.

| The CBRC Series tempering line is advanced technology of Glaston’s renowned CB concept (Continuous Batch) tempering furnace model and can be operated both in continuous and batch mode.

| Watch a demo how automation helps to run a glass tempering line without any prior experience

| Fenestration BAU China and CADE Architectural Design Expo as the pageant of Fenestration BAU had a grand opening on 29th, October 2020.

| Taking small steps to answer evolving customer needs

| Each Fox includes all distinctive and proprietary innovation of Mappi technology.

| Explore Hegla's extensive product portfolio of machines and systems for flat-glass processing.