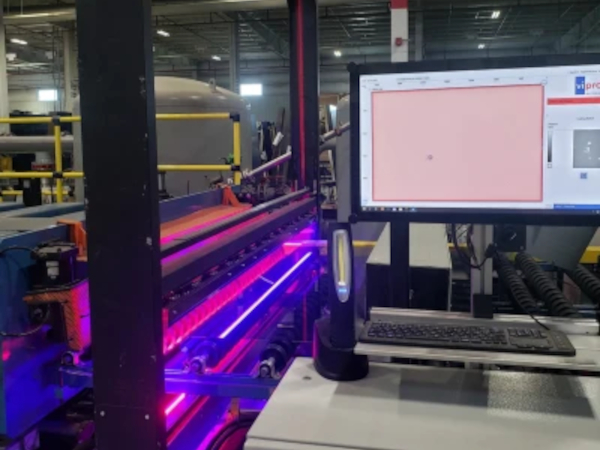

The SIL 2015 version is definitely focused on Plant Performance Management. SIL Dashboard is the perfect tool for managers and operators to follow up efficiency at a glance and in real time, allowing direct access to main KPI for more detailed information. 2015 new features include the management of variable equipment, in order to schedule equipment changes and improve general performance in the plant. Discover in this catalogue other developments made along the year to meet our customers’ requirements.SIL 2015 version also reflects the adaptation of the system to others areas of activities of the glass markets such as bottle decoration, tableware, glass tubes, and float glass.More at: www.vertech.eu/Document-Library/SIL2015-new-functionalities-catalogue.pdf

The SIL 2015 version is definitely focused on Plant Performance Management. SIL Dashboard is the perfect tool for managers and operators to follow up efficiency at a glance and in real time, allowing direct access to main KPI for more detailed information.

2015 new features include the management of variable equipment, in order to schedule equipment changes and improve general performance in the plant.

Discover in this catalogue other developments made along the year to meet our customers’ requirements.

SIL 2015 version also reflects the adaptation of the system to others areas of activities of the glass markets such as bottle decoration, tableware, glass tubes, and float glass.

More at: www.vertech.eu/Document-Library/SIL2015-new-functionalities-catalogue.pdf

![]() 600450

600450

www.vertech.eu

2015-01-12T12:00:00

SIL 2015 improvements and new functionalities

glassonweb.com

Add new comment