Others also read

The entire construction and commissioning was supervised and managed by HORN®.

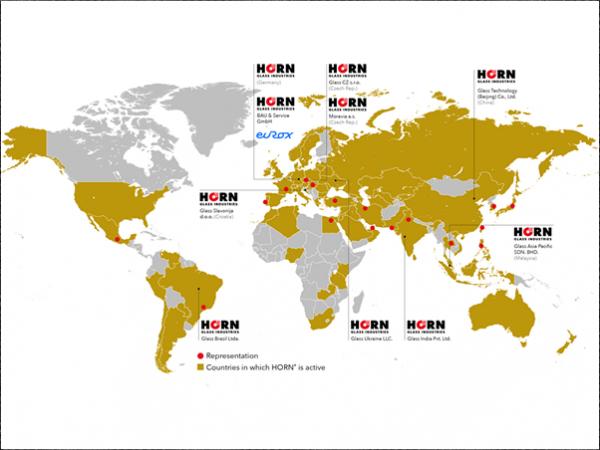

Products by HORN® Glass Industries stand for quality and reliability. HORN® customers all over the world appreciate this claim.

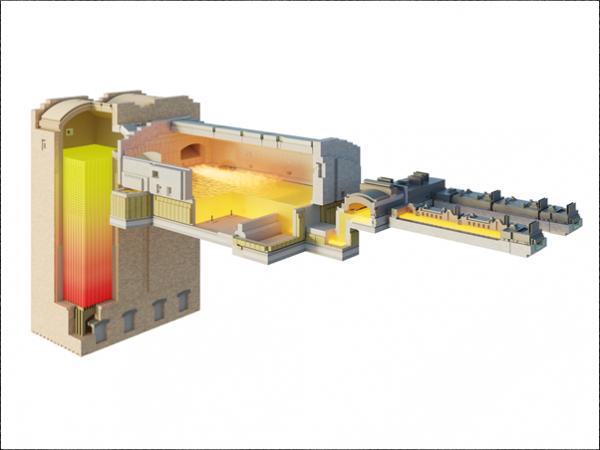

The furnace is designed in appliance with the most advanced technology and a maximum melting output of 290 t/d to produce either 290 t/d flint or amber glass or 280 t/d green glass.

Vertec Mill is designed for high productivity purposes due to the possibility of drilling holes with opposed bits and milling cutters on every type of glass that has a straight side.

The Liverpool City Region will benefit from £54 million investment to revitalise its glass industry and support the region’s economic recovery.

The awards, now in their seventh year, will take place this year virtually on 12 November and will again celebrate the achievements of the glass industry and its supply chain.

HORN® Glass Industries will show you a film of how a glass melting plant grows, exhibit 24 products and support the technical lectures in the MELTING session on Tuesday, October 27, 2020 as sponsor.

The Belarusian company JSC "Grodno Glassworks" Elizovo Branch has appointed HORN® Glass Industries for the construction of a modern end fired furnace with a maximum capacity of 180 t/d.

What needs to be considered when using infrared thermometers, IR cameras and our new glass inspection system in different glass applications?

The Cms Profile is the ultimate vertical CNC work-center. It can mill, drill, grind, polish, engrave, and seam.

Even in the segments that were hardest hit by the coronavirus crisis the indicators are looking more positive again.

HORN® Glass Industries AG offers customer proximity and short response time on the global market.

Six trainees will be joining the workforce of HORN® Glass Industries AG this year.

Şişecam Group gets approval from shareholders to unite all operations under a single entity

This year in April HORN received the order for the repair of furnace 1 for the plant in Steinbach am Wald, which is an 82.8 m² end fired furnace.

Şişecam Group reports investments of TRY 625 million in the first six months of 2020

When enhanced with Fenzi products, glass plays an increasingly crucial role in the world of packaging.

HORN supplied the end fired furnace designed with appliance of the most advanced technology to save energy, reduce emission values and extend furnace life.

Şişecam Group received approval from the Capital Markets Board for its plan to simplify in its legal entity and shareholding structure.

CMS’s definitive solution for the complete manufacturing of refrigerated display cases.

Through participation in CERICOM LiSEC is expanding its competence in offering innovative solutions for the processing of flat glass and technical glass lites sheets by means of laser.

The co-operation between Glas Lang and LiSEC began with investment in a LiSEC laminating system.

At the moment, the workers are smoothly plastering the inside and outside of the masonry and completing the electrical installation.

Gennady Bugrov (RGC): “Organisation and efficiency are our greatest strengths. And now we're investing in the future”

Since the beginning of February, employees of HORN Glass Industries AG have been on a construction site in Orizaba, a city east of Mexico City, in order to set up and commission a glass melting plant for its customer SIVESA.