Others also read

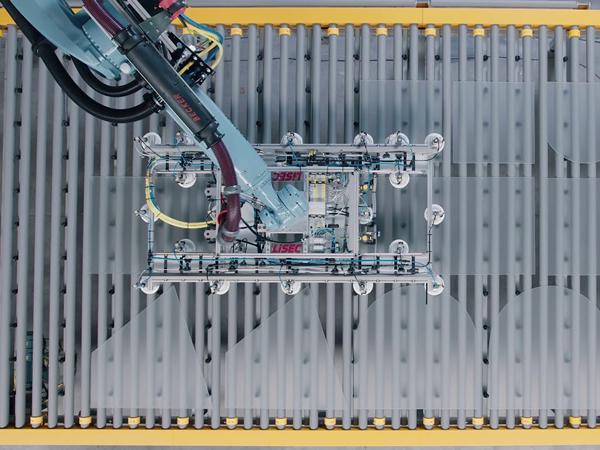

Find out everything about the LiSEC furnace bed loading and unloading with robots in today's video!

The Elb 9 + 2 is capable of producing a complex profile on the edge of the glass in a single pass without the need to process the glass on different machines or change setups.

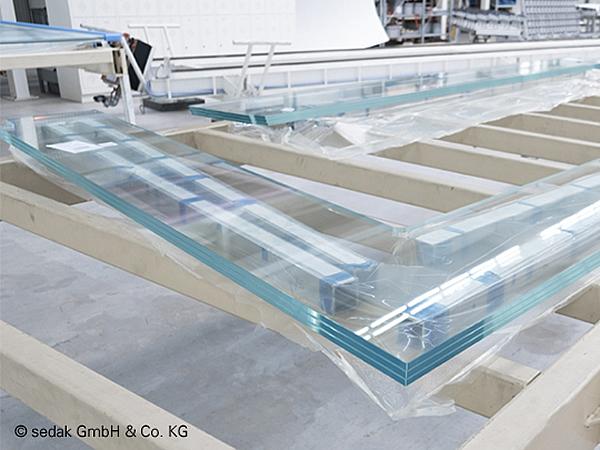

The new hybrid convection oven for the production of laminated glass guarantees maximum versatility during the glass lamination process.

Bovone has always protected its team: certification of compliance with the new ISO 45001 global standard which regulates the management systems for the safety and health of workers arrives.

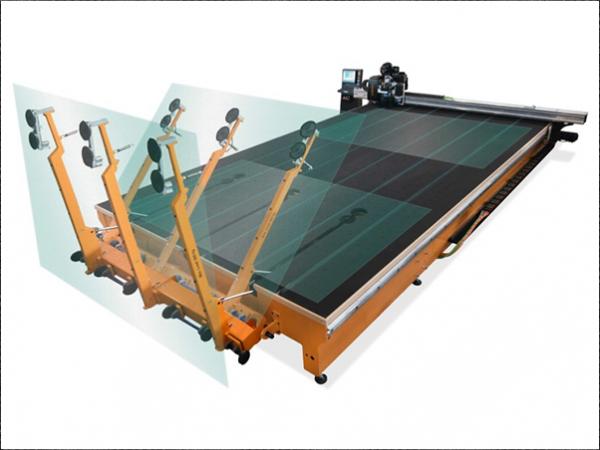

The Rapidstore, as an automated storage system, simplifies manufacturing methods and gives business owners greater capacity.

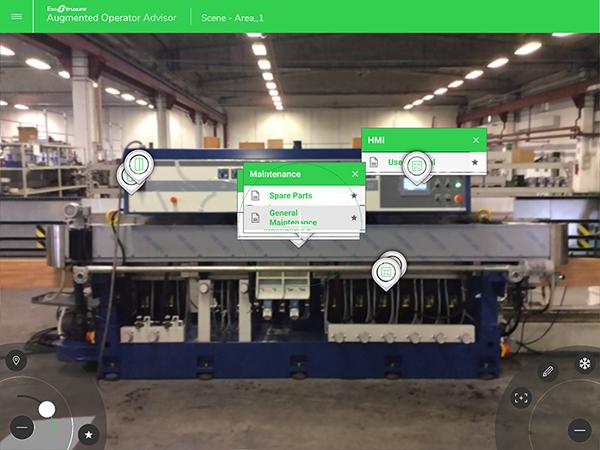

The contribution of Bovone to the advancement of the glass industry towards the 4.0 horizon.

Industry 4.0, digitalization of processes, remote assistance: the levers of Bovone Group to enhance the business of its customers.

The process of affirmation of 4.0 technologies on the current industrial scenario saw a significant acceleration in 2020.

This presentation documents the proper handling methods and processing conditions for the lamination of SentryGlas® SG5000 and SentryGlas® Xtra™ (SGX™) SG6000 ionoplast interlayers.

Gaining digital added value and simplifying workflows are the focus of the HEGLA Shop-Floor app, which is available in tablet and smartphone versions.

Between 27 and 30 October 2020, the virtual LiSEC Campus will be welcoming visitors from around the world.

With a long-established history in glass machinery manufacturing, HEGLA has developed a fully automated, in-line, blade trimming system that provides greater accuracy and speed.

In this year of unprecedented change there have been positive developments at HEGLA UK.

What C.Bergmann appreciates most about the 32 years of cooperation with LiSEC is the consistently high quality of the long-lasting LiSEC machines and the tangible proximity to the customer.

The TUROMAS loading system offers multiple benefits for glass processing companies, including productivity increase, optimization of plant layout, economic savings or factory safety.

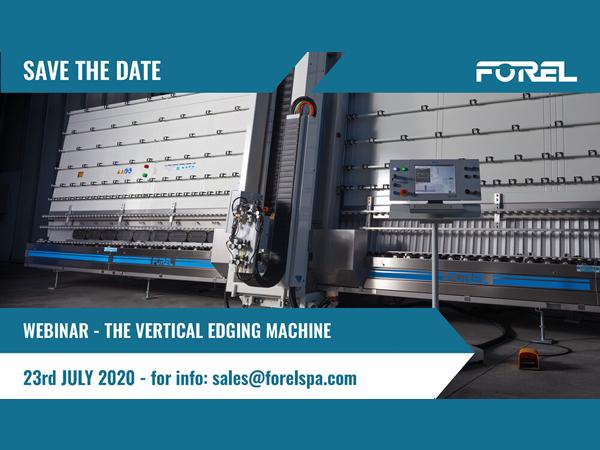

After the great success of its first Webinar experience, Forel is inviting all its customers to a new appointment with glass processing technology.

All-glass optics not only for facades, but also for glass roofs.

The new V-H 150 Seculift from HEGLA is next generation glass handling technology for lifting, placing and manipulating glass on a production floor.

Eastman Machine Company announces that it has appointed Technical Cutting (TeCS) of Nottinghamshire to represent its line of automated cutting systems in the UK and Ireland.

HEGLA has stood for high-quality, high-performance machines and systems for flat glass processing since 1976. These are the principles that have characterised and informed our work ever since.

With modern logistics software and a clever delivery app, A+W provides insulating glass manufacturers and glass processors with tools for dispatch control that ensure punctual delivery with the highest product quality.

The Van Noordenne Groep owns one of the most remarkable Forel’s Sorting Systems in the world!

With the new V-H 150 seculift, HEGLA and the HEGLA New Technology present a new generation of the V-H suction device.

Mr Rákosy is generally extremely satisfied with the cooperation with LiSEC. In particular with regards to service and spare parts availability.