Date: 22 February 2010

This recent addition to the HB Fuller range of edge sealants has many advantages over other insulated glass unit sealants available on the market, including: Application temperature is 110-120°C compared to traditional hot melts with application temperatures of 170-195°C. This means that there is far less heat conducted through the spacer bar and glass. This greatly reduces the level of deflection in your units. The unique character of this product means sealant depths as low as 3mm are achievable without compromising the quality of the sealed unit. This can help towards gaining higher Window Energy Ratings. This sealant has a full moisture-sensitive cross-linked curing system which provides a strong chemical bond to the glass and spacer system. This is unlike all other butyl based hot melt sealants which rely on a purely physical bond to the glass and spacer system. Once cured, Warm Melt is an elastomer which provides a solid seal that will not move or slip in the presence of heat. Warm Melt provides the same production and handling benefits as those of traditional hot melt sealants. Mark Hickox, Sales Director at Thermoseal Group says: “We have already spoken to many customers who are thrilled that this sealant will help to improve Window Energy Ratings, but perhaps one of the most promising areas for application of Reactive Warm Melt will be in the production of conservatory roof glass.This glass is exposed to high surface temperatures which can cause standard Hot Melt’s to slump dramatically, whereas Warm Melt will not.”

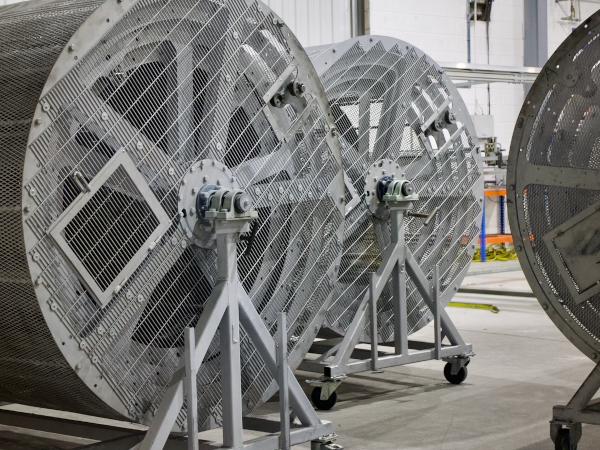

Reactive Warm Melt has been tested to EN1279 parts 2 and 3 with metal and foam spacer systems. It is supplied in 20ltr and 200ltr drums which will fit most drum loading hot melt robots or small drum dispensers.

Click here for further product information.

Add new comment