Date: 23 May 2012

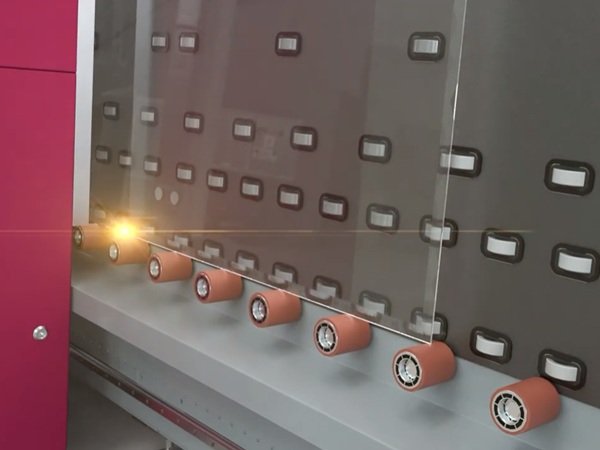

Retro-fitted to one of our existing Lisec IG lines, this press now means all sealed units made by Clayton will benefit from the consistency, accuracy and speed only flood filling of argon gas can bring. To be installed in July 2012 this equipment will boost our overall argon filling capacity to 14,000 units weekly and remove the need for drilling though spacers and unsightly corner keys.

Furthermore, given the rising demand we are now seeing for triple glazed units, both presses will be upgraded to fill dual cavity units, now making gas filling of triple glazing a fully automated process. With this method, using standard Planitherm Total + or Pilkington KS and argon gas we are able to manufacture U-values down to 0.6 W/m2/K in a 44m IGU and 0.8W/m2/K in 36mm overall unit.

Add new comment