Date: 22 April 2011

In a recent contract the company was asked to supply and install a 4 headed edging machine from the Zafferani Glas range at Draks.

As a specialist manufacturer of stylish and innovative internal door systems for the building industry, Draks has established a reputation for providing a range of top quality sliding door and wardrobe products, offering one of the widest ranges of styles currently available in the UK.

When the Oxfordshire based company designed a new wardrobe range specifically for one customer, it was essential to evaluate manufacturing procedures. The new ‘Skyline’ range required a specific style of mirror to be incorporated onto the back of the doors. Being small detailed panels the edging for the finished product needs to be commensurate and exact. The Zafferani Glas company has a long history as a manufacturer of glass working machinery, being at the forefront of technology and design innovation. It therefore made the ideal choice for recommendation from Darren Bill, Sales Manager when discussing a solution for improving Draks production methods. Draks provides products for windows, internal spaces and roofs that will complement contemporary or traditional interiors creating concepts from initial design and specification to the final installation, so production methods have to be swift and precise to meet the fast-moving requirements of the customers.

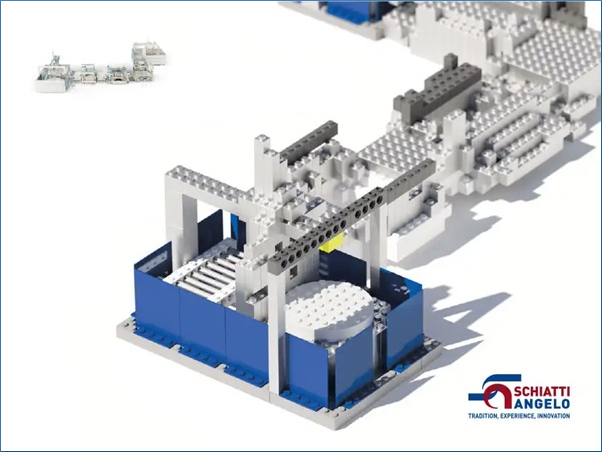

Consequently, a Zafferani Flat4 FPE was purchased and recently installed into a dedicated manufacturing area at Draks Head Office. This electronic straight-line edging machine with 4 cup wheels is used for the production of flat edge with arris which will greatly reduce production time. Additionally this will now also reduce time taken to measure and install the Skyline products. The company considers bringing these manufacturing skills in-house will enable the Draks team to adapt the edging equipment for other processing requirements.

The Zafferani equipment will help to greatly reduce lead times as production would previously have been outsourced. Furthermore the company can now provide a more responsive customer service with a faster turnaround.

Chris Ayres, Managing Director at Draks considered investment vital and was impressed at the highly efficient installation procedures provided by The Glass Machinery Company. A team of skilled engineers headed up by Phil Birchall, Managing Director arrived on-site and completed the installation, including staff training all within one day. Chris Ayres comments, “Our in-house manufacturing facilities will allow us to respond to short and demanding lead times as well as giving us complete control over product quality.

Our entire range incorporates the most simple and cost effective products to the most specialists and customized. With the new edging equipment we can now grow the Skyline range and further develop our product portfolio We were aware of the top quality products available from The Glass Machinery Company, so knew that we could rely upon the equipment and support services. We have not been disappointed, with both product and training being excellent. We consider this investment has extended our manufacturing capabilities adding another dimension to our already extensive range of wardrobes and internal sliding door systems which will further bolster our market position.”

Phil Birchall, The Glass Machinery Company comments, “The entire team takes pride in offering customers a comprehensive and professional service; we are always prepared to go the extra mile and will provide a fast solution to all sized manufacturers requirements. It is extremely satisfying to know that we are recognized for the complete range of products and after-care services we provide and are very happy with the successful installation at Draks.”

Ends

Add new comment