Date: 15 August 2005

At FESPA 2005 in Munich, Sefar presented a new screen printing mesh that was specially developed for printing with UV and other difficult inks.

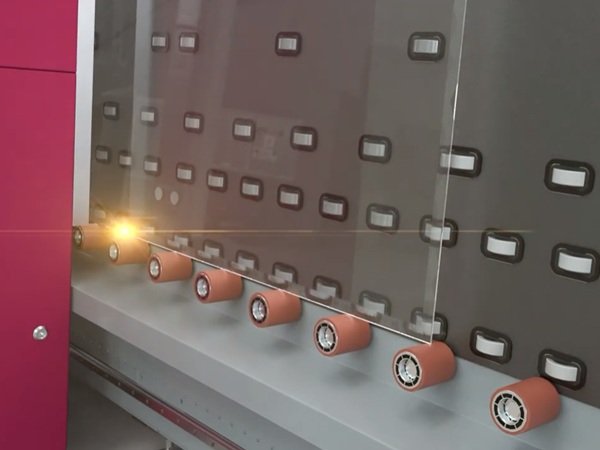

New SEFAR® LFM (Large Format Mesh) meets the highest demands for printing onto expansive surfaces like posters, glass, etc. Even difficult translucent inks and exacting patterns reproduce with top quality.

1. Finer threads, larger mesh openings

Printing large areas is tricky with conventional screen printing mesh. Translucent and other difficult inks are prone to form stripes and lines in the printed image, which can cause major difficulties.

Screen printing mesh in current use is typically woven from threads with a diameter of 34 , which at a thread count of 140-150/cm results in very small mesh openings. This frequently leads to the risk of imprinting the mesh structure, or producing a wave-like moiré when overprinting the same surface with multiple inks.

New SEFAR® LFM features threads with a reduced diameter of just 32 microns. The result: for a given thread count, the mesh openings are remarkably larger. That increases the open surface area, which improves ink flow and makes it more even. SEFAR® LFM also uses a modified weaving process, so not only are the mesh openings larger, they are more precise as well.

These measures stop stripes and lines from forming when printing with translucent and otherwise critical inks. Ink deposit is more even, and it is possible to achieve finer tone gradations as well as better edge sharpness with fine lines and screen dots. Greater reproducibility on subsequent print runs is another quality characteristic of this mesh.

Stronger thread, reduced mesh elongation, less relaxation in tension

SEFAR® LFM mesh uses a new type of thread material, specially developed for Sefar. Despite its reduced diameter of 32 microns it is extraordinarily resistant to tearing, and also exhibits reduced elongation as well as only a modest relaxation in tension.

Until now, insufficient thread strength prevented the use of screen printing mesh with thinner threads and hence larger mesh openings in large-format printing. But with this new thread material, SEFAR® LFM mesh can be stretched on even the largest printing frames to practically the same tensions as conventional high-modulus mesh with threads of 34 micron diameter. So the existing stretching process can be retained without modification, despite the finer thread material.

Mesh elongates during the stretching process, which reduces the thread count per cm. The greater the elongation, the greater the loss in thread count.

SEFAR® LFM elongates less than other screen printing meshes to date. The thread count of the stretched mesh remains noticeably higher. That in turn improves the printing resolution and optimises print quality. There is also reduced risk of moiré effects.

Because the new mesh exhibits markedly less relaxation in tension, the same stencil can be used over longer print runs, and/or the mesh can be re-used more often. This brings a considerable cost advantage.

Thin mesh with specially treated surface

Thinner threads reduce the mesh thickness. So ink consumption is practically unchanged despite the larger open surface area, which is especially cost-relevant with expensive UV inks.

Moreover, SEFAR® LFM exhibits a series of other properties, like:

Better adhesion of the stencil material:

Fine screen dots and lines stay firmly anchored in place.

Improved wetting:

Emulsion distributes itself more evenly on the mesh: coating thickness varies less, tolerances are closer. That means greater process reliability.

Better ink flow and release:

A more constant and homogenous ink deposit, high-quality printing results, especially with translucent and other difficult inks.

No mesh degreasing:

Thorough rinsing suffices, saving both time and chemicals

Greater efficiency:

Optimised stencil-making, no degreasing and wetting agents necessary, improved productivity, fewer ghost images.

Add new comment