Date: 21 February 2008

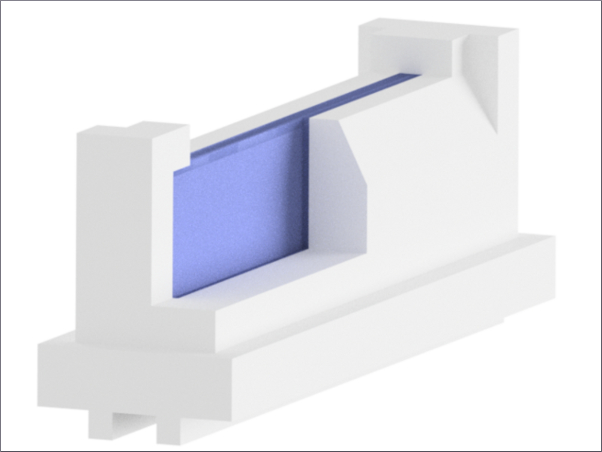

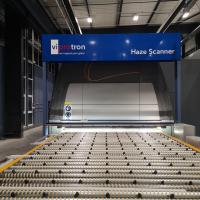

Masaki is examining Pilkington's IGU design and manufacturing processes, to see how they can be improved in order to achieve a higher quality product. And Tamaki will be focusing on overall quality improvement at two specific sites.

"We know we have room for improvement at some of our sites," said global quality manager Simon Watkins. "And where quality performance is good, we want to see if we can raise the bar. In other words we want to make the lower performers good - and the good ones even better."

Downstream product quality in Japan is literally 100 times better than in the UK, with returned parts running at 250 ppm, compared to 20 -30,000.

"We recognise that Japan is years ahead of Europe in terms of the priority it puts on quality and service to the customer," said downstream operations director Gary Charlton. "To have two such experienced managers giving us six months of their time is a fantastic opportunity for us."

Add new comment