Latest articles

| This first episode is devoted to the white haze phenomenon – one of the most asked about issues in the history of #AskGlaston.

| This latest Glastory blog by Miika Äppelqvist is dealing with the areas of the tempering process that can be improved to make operations more efficient.

| Industry demand for impeccable glass quality has increased notably over the last years. Customer expectations run high, forcing glass processors to strive for ever-stricter quality control and ensure minimal rejection rates for finished products.

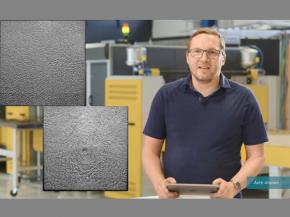

| The most common quality issues that arise in tempered glass are roller waves, glass distortion, bad anisotropy and white haze. In this post, we want to focus on white haze and ways to control it.

| In 2015, the bold concept of a curvy tower at 252 East 57th Street, New York, was presented to an audience at the Glass Performance Days conference. At that time, building construction was just beginning, and no one was certain such a novel idea…

| In glass edge processing, the requirements for the finished components can vary greatly depending on the location and purpose.

| In glass tempering, we look for equipment that uses less energy, leading to fewer emissions. But sometimes, the numbers are too good to be true.

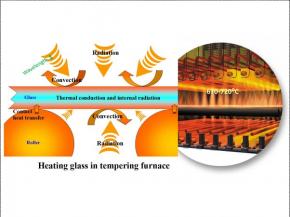

| Global environmental concern is motivating efforts to improve energy efficiency in all industrial sectors. And glass tempering is no exception.

| Full convection, forced convection, focused convection, recirculated convection – the list of terms goes on and on.

| Bent and tempered glass has long been of great interest to the market. The process of creating high-quality tempered bent glass has evolved over the years.

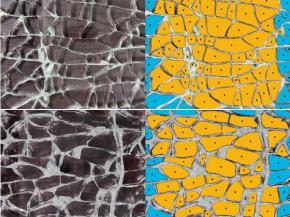

| Do you still spend precious time doing the meticulous task of manually counting glass cullets for a glass fragmentation test? Or maybe your modern counting tool is not exactly the gold standard? If so, we have some good news for you!

| Irregularities in the glass, which are visible under certain lighting conditions and interfere with the overall impression of a pane – anisotropies – occur when glass is tempered.

| Glaston is working hard to make tempering furnaces more automated.

| It is a very known behavior that the glass fragmentation depends on where you break the glass.

| In this paper, the basics of the heat flux modes are given, a solution method for the glass energy equation is introduced, and some tempering furnaces are theoretically studied to show the portions of the heat transfer phenomena inside furnaces…

| In this paper local heat transfer of impinging small jets on surface heat transfer and residual stresses is studied.

| The fragment count in the standardized fragmentation test in the standard EN 12150-1 is the way to define the safety level of tempered glass and a way to also get an indication about the stress and strength level of the tempered glass.

| The author proposes a simple surface quality test using a standard window cleaning scraper and common smartphone or shop microscope.

| Learn about the first step we take in maintaining tempered glass quality standards.

What do power consumption, installed power and installed capacity of a glass tempering furnace mean?

| Power consumption of the glass tempering furnace refers to the amount of electric energy consumed in the process of tempering certain quantity of glass. The measuring unit commonly used is the kilowatt hour (KWh).