This paper was first presented at GPD 2019 by Mr. Florian Gast from Dr. Siebert Consulting Engineers.

Mr. Gast, M.Sc., IWE studied civil engineering at the Technical University of Munich. As part of his master’s thesis, he did research on silicone adhesives at the University of the German Federal Armed Forces Munich. Since 2019 he works at Dr. Siebert Consulting Engineers.

1 Abstract

Silicone sealants have been applied for more than 40 years to structurally bond glass onto steel or aluminium frames. One of the reasons is the unique resistance to weathering in normal assembly situations.

With vertically installed facades, there can be installation assemblies with horizontal silicone joints, on which standing water cannot be avoided. Despite the assumed, good weathering resistance of silicone, this particular situation must be investigated.

At the University of the German Federal armed forces Munich, Silicone samples were artificially aged in various chemical solutions and analysed using microcomputer tomography and infrared spectroscopy to describe the ageing behaviour.

The investigations show the suitability as well as challenges of the chosen methods for the description of the ageing behaviour of silicone sealants.

2 Introduction

Adhesive bonded joints are dimensioned using appropriate models or technical rules. In addition to a multitude of relevant boundary conditions for the design, the durability depending on the environment of the bond is of great importance. Frequently, uncertainties are estimated with general safety factors in the dimensioning. At this point, a need for research arises from the goal of enabling the more economical and lean constructions at a sufficient safety level. In the course of the investigations, the special case of standing liquid on a silicone sealant was analysed.

Distilled water, saline solution and sulphur solution were selected as ageing solutions. The concentration of the solutions, as well as the selected test period of 42 days were based on ETAG 002 [1]. The latter concentration simulates the attack by acid rain. The material is stored continuously for 42 days, which is clearly on the safe side in relation to bonding used in a building construction, since a correctly executed adhesive joint usually dries after precipitation.

By means of the methods chosen, a possible ageing process of the samples across the cross-section is to be described. Among other aspects, the chemical composition in the unaged and aged state is analysed and evaluated.

Figure 1 shows the tested samples. On the left side of the picture a sample with a cylinder height of about 32mm is shown, from which the 8mm high sample for microcomputer tomography and the 1mm high sample for infrared spectroscopy (on the right side) was extracted.

3 Analysis by microcomputer tomography

Microcomputer tomography is a computersupported, non-destructive measuring and testing method with which test specimens can be digitally reconstructed. It is used in numerous areas to record internal structures by means of radiography. Technically, the procedure is basically the same as computer tomography known from medical technology, but differs in the generally smaller dimensions of the device and the test specimen as well as a significantly higher possible resolution, so that very small components can be reconstructed in detail.

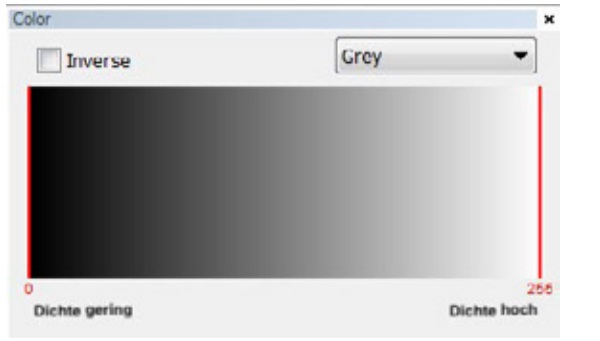

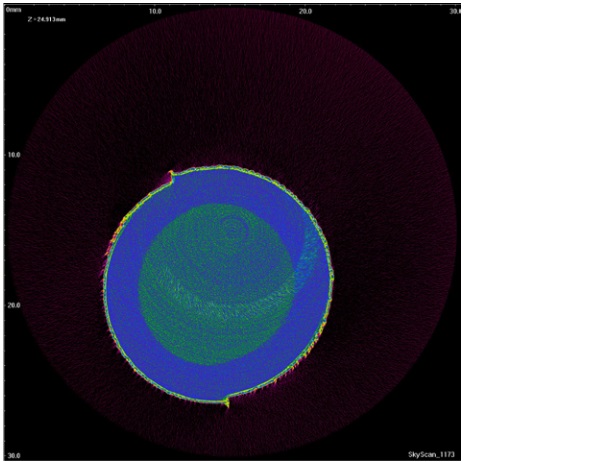

By radiating the body, not only the outer geometry but also the inner geometry can be represented in a digital image. The raw data are assembled to a three-dimensional model consisting of voxels in which density information of the test piece is available at every point. This information is output qualitatively on the basis of a degree of blackening. For the representation you can choose between a less sensitive black and white scale, see Figure 2, and a much more sensitive coloured scale, see Figure 3.

Due to the very homogeneous composition of silicone, even in the damaged state and because higher sensitivities lead to disruptive effects, the challenge is to choose the right sensitivity. After numerous preliminary tests, it was possible to select the right sensitivity. According to Johlitz [1] it is assumed that damage to the material can be observed with the chosen method.

The analyses were performed with the Skyscan 1173 micro-CT spiral scanner from Bruker, shown in Figure 4, with a minimum possible voxel size of 7µm.

Over the test period of 42 days, samples were regularly taken from the solutions and analysed. Over the entire period, no changes in the samples were detected.

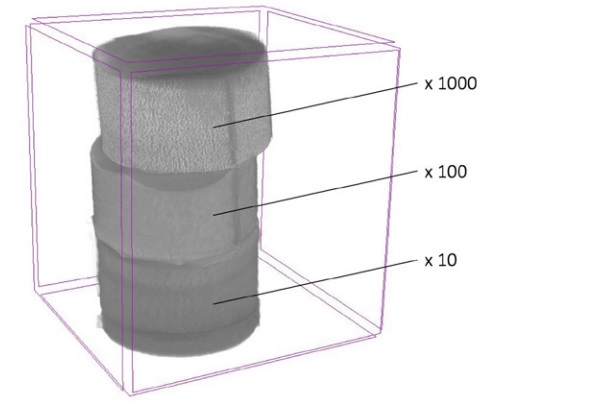

As the durability of the material and the usability of the method in combination with polymers are to be investigated, an attempt is made to artificially damage the material. In the first step, the ageing process is increased to 100 days. This effect is not to be expected due to regular drying of a joint in a properly executed facade. In all tested solutions, no damage is found after 100 days of permanent storage. In order to cause damage to the material due to artificial ageing, the storage concentrations should be greatly increased in the second step. A solution with ten times (x 10), a solution with one hundred times (x 100) and a solution with one thousand times (x 1000) sulphuric acid concentration were prepared. Samples are stored in the solution for 7 days during this examination.

The prepared solutions do not correspond to any naturally occurring concentrations. The tests should not simulate environmental scenarios, but only damage the material so that damaged material can also be analysed.

The artificially aged samples are scanned on top of each other as shown in Figure 5.

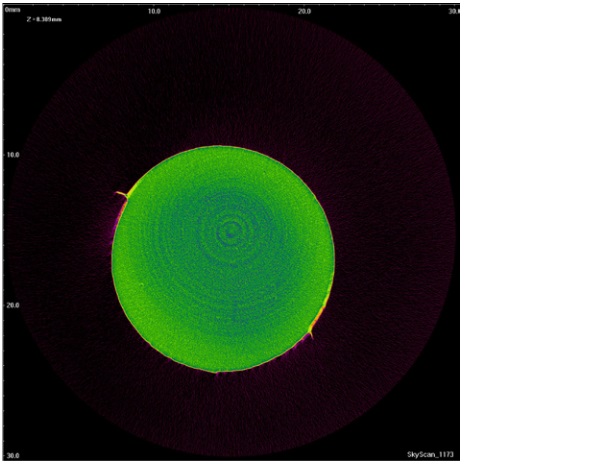

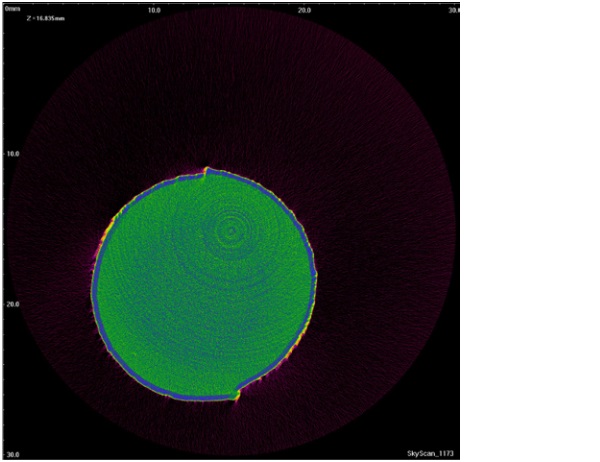

A cross-section of each sample is shown in Figure 6-8.

Even at ten times the concentration, no damage can be detected in the CT scan after 7 days of storage.

Significant changes can be observed at hundreds and thousands of times the concentration of sulphuric acid. In terms of quality, the density increases in the edge area, which indicates the diffusion of substances from the solution into the sample.

4 Analysis by infrared spectroscopy

Infrared spectroscopy is a very fast and accurate method for the analysis of polymers. Due to the very accurate results that can be achieved in a very short time, the method is also state-of-the-art in industry, e.g. for the identification and quality control of plastics [2].

The assumption made that damage to the material can be detected by differences in density in the CT scan is to be checked by infrared spectroscopy. This is a method with which the chemical composition of a material can be examined very precisely. By comparing different samples, even the smallest differences can be detected and evaluated.

IR spectroscopy was performed with the Thermo Fisher Scientific analyser shown in Figure 9.

![Figure 9: FT-IR-spectrometer by thermofisher scientific, Type NICO_LET iS10 [1]](/sites/default/files/inline-images/Fig9_43.jpg)

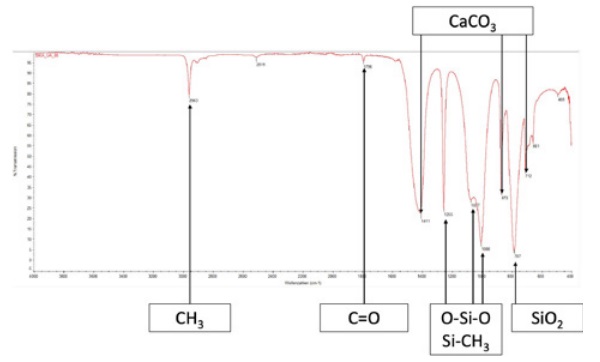

With infrared radiation of the sample, the chemical composition of the sample can be deduced from the measured transmission of the radiation at different infrared wave numbers.

Figure 10 shows the entire measured transmission spectrum of an unaged sample. The transmission values in % of all peaks are given per cm-1. The detected components are indicated as the result of a comprehensive analysis.

The results of microcomputer tomography can be checked by the analysis of artificially aged samples from ageing solutions according to ETAG 002 [1] over 42 days. No significant deviations from aged and unaged specimens can be detected when the transmission spectra are superimposed. The results from microcomputer tomography and infrared spectroscopy are consistent.

Even if the samples are stored for 100 days, no changes in chemistry can be detected over the entire cross-section of the samples.

As in section 2, samples from highly elevated sulphuric acid solution were also tested.

At 10-fold and 100-fold concentration, no change in the chemical composition can be observed either. The narrow damaged layer in the CT scan with 100-fold concentration cannot be detected in infrared spectroscopy due to the method.

A significant reduction of calcium carbonate (CaCO3) and thus a change of the material can be observed at 1000-fold concentration. Calcium carbonate is used as a filler in silicone adhesives. When these substances are dissolved, water molecules can diffuse into the sample, causing mechanical damage to the material. In undried samples, water molecules could be detected in the transmission spectra.

5 Summary

In the investigations carried out, microcomputer tomography and infrared spectroscopy were used to analyse an artificially aged silicone. An interesting feature of the methods chosen is the possibility of directly evaluating the internal structure of samples instead of comparing mechanical values, which can ultimately lead to a better understanding of ageing processes. The results of the two methods agree well in the investigations carried out.

The artificial ageing of specific silicone samples in liquid solutions according to ETAG 002 [1] showed a high chemical resistance.

By the artificial damage of samples by means of ageing solutions with extremely increased concentrations, which have no relevance for the planned use in facades of such adhesive joints, it was shown that the results of the methods agree also with damaged samples.

References

[1] EOTA, “ETAG002 - Guidline for European technical approval for structural sealant glazing kits (SSGK) - Part. 1,” EOTA, Brüssel, 2012.

[2] Thermo Fisher Scientific, “Produktinformation Nicolet iS 10 FT-IR-Spektrometer,” [Online]. Available: http://www.thermofisher.com/order/catalog/product/IQLAADGAAGFAHDMAPC. [Accessed 04 Oktober 2018].

[3] Bruker Optik GmbH, “Laborpraxis Vogel: Schnelle Polymeranalyse mittels FT-IRSpektroskopie,” 24 September 2013. [Online]. Available: https://www.laborpraxis.vogel.de/schnelle-polymeranalyse-mittels-ft-irspektroskopie-a-406780/. [Accessed 04 Oktober 2018].

[4] M. Johlitz, Zum Alterungsverhalten von Polymeren: Experimentell gestützte, thermochemomechanische Modellbildung und numerische Simulation. Habilitationsschrift, München, 2015.