Date: 10 November 2014

Aesthetic. Proven since 1994.

Conventional insulating glass with metal spacer transfers the heat or the cold respectively to either the inside or outside, which consequently does not provide an ideal thermal insulation. The organic polyisobutylene spacer without metal insert provides a best possible thermal insulation and, subsequently, reduces the U-value by up to 12% compared to a conventional window with an aluminium edge seal.

Consequently, the highest standards in thermal insualtion are met. As heating costs are ruduced, subsequently so is condensation. „The use of TPS®provides significant advantages for all parties,“ says Klaus Puschmann, Manager Product Management of Bystronic glass. „From insulating glass producers, window constructors and architects to the owners, who use this product ultimately, everyone benefits.“tps_scheibe

Aesthetic and individually adjustable

It is possible now to address the individual customer wishes and position the seal where desired. For instance in an almost invisible position in the corner. The application and seamless sealing of the TPS®spacer is performed in a single step. The advantage: The gas-tight bevel joint that has been proven repeatedly does not require any thermal-mechanical reworking. Irrespective of radii, small or large spaces between the lites, this seal always works and is the distinguishing feature of the TPS®edge seal by Bystronic glass.

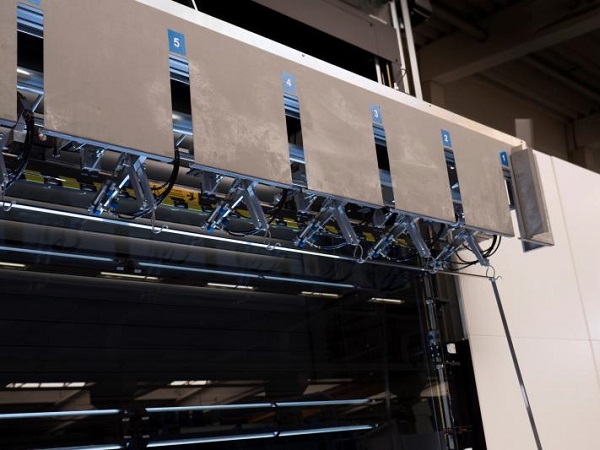

Spacer production is integrated nowadays

Production of insulating glass is greatly simplified thanks to the direct application of thermoplastic material onto the glass. The spacer width can be varied during production for each insulating glass unit in the process cycle. Separate production processes are no longer needed for sawing, bending, connecting, desiccant filling and butyl-coating. „This saves both time and money,“ explains Klaus Puschmann. „Fabrication of the entire production mix is now possible on a single line. The storage of different spacer profiles and connectors is eliminated, because the suitable spacer is readily available.“

Add new comment