Date: 22 June 2010

Approximately 300 variants of insulating glass units in many different glass formats and with a variety of spacer widths are produced here – manufactured on two lines from Bystronic glass.

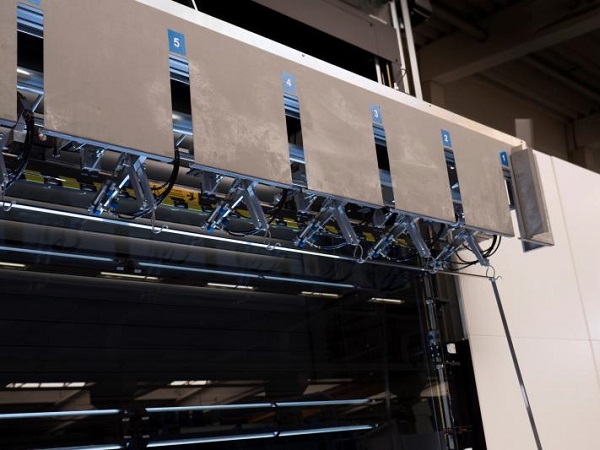

In the right hand part of the bespoke factory building, immediately after the offices, is a sprawling production area, where the two insulating glass lines are installed in a mirror-image arrangement. Each is equipped with Bystronic glass’ flexspacer applicator for applying the warm-edge spacer product, Super Spacer®. Metallic spacers can also be processed on the dual capability lines. "When we invested in the first Bystronic glass line in 2007, we were the first company in Scotland automating the production of insulating glass units with Super Spacer®," remembers Nicholas G. Cunningham, Chairman of Ravensby Glass. Managing Director, Gordon B. Dickson adds confidently: "We took the right decision relying on the machine technology from Bystronic glass for the production of insulating glass units. In order to offer high product quality, high-quality machines are also required."

Customer proximity as the key factor

It now reads like a very simple success story. However, it was preceded by longer story: Ravensby Glass Co Ltd, the company on the east coast of Scotland , is a subsidiary firm of what was once one of the largest jute manufacturers in the region. For this reason, the company fits perfectly into the picture of the city: Apart from Jam and Journalism, Jute took its place as the other "J" to become a vital element of Dundee 's “3J’s” economy. Then in 1988, Ravensby Glass started its insulating glass production and jute processing ceased four years later. Today, the company focuses entirely on glass processing for private customers and larger enterprises within the UK . The first contact with Bystronic glass was made when the supplier of system solutions for glass processing established a subsidiary for sales and service in the UK in the year 2000 – for Ravensby Glass a key factor. "We place great value on close proximity to the supplier, professional training of our personnel at the machines, and especially excellent customer service," explains Kevin Small, Production Director.

During the following years, Ravensby Glass initially purchased two butyl applicators from Bystronic glass. "Due to the positive experience with the technical performance and especially the service, Bystronic glass was shortlisted immediately when further investments were on the agenda," he explains. This was the case in 2006, the year when Ravensby Glass decided to process the Super Spacer®.

Fast and accurate work

While visiting reference customers of Bystronic glass in the US, Ravensby was convinced of the quality of the flexspacer applicator, and the decision was taken following attendance at the trade exhibition Glassbuild America 2006. "Ultimately, we selected the supplier with the best customer service," says Kevin Small, who also describes the machines as extremely user-friendly. "We are convinced of the quality and technical advantage of the Bystronic glass machines," he explains and highlights the V-shaped conveyor system as an example.

However, before it was possible to transport the first unit on the V-conveyor, a particular challenge had to be overcome. An extremely tight schedule was placed on the delivery of the line and commissioning had to be completed quickly. For Ravensby had to fulfil ongoing customer orders on the one hand, and on the other hand, order books were full and fixed delivery dates for the first insulating glass units with Super Spacer® had been agreed upon already. "Bystronic glass identified our requirements for machines, and the related service, and offered a solution perfectly tailored to our needs," Nicholas G. Cunningham stated. He commends the smooth cooperation, which he can see in each of more than 250,000 insulating glass units produced annually.

Add new comment