Others also read

Weekly updates on a range of subjects to help fabricators improve what they do while also building on to their bottom lines. Virtual Open Houses and Live Demos available for all lines for immediate access.

VITROCHAVES talks about customer orientation, the importance of reliable solutions, and 40 years of growing together with LiSEC.

Mastering the tempering process has been considered a very difficult or even a mystical art form, but it should not be!

Glaston, a pioneer in cutting-edge glass processing technologies, continues to advance automation solutions that improve the quality, efficiency and profitability of glass tempering.

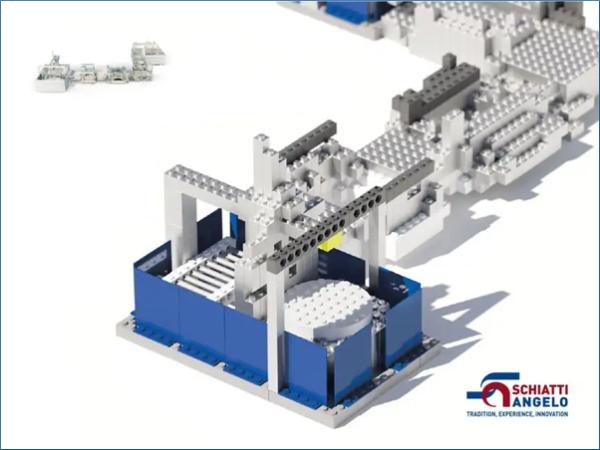

Schiatti explores the potential of connecting various machines across different lines to craft complex processes marked by high performance and precision.

The agenda at glasstec 2024 features topics that keep the glass industry busy: Decarbonisation, Circular economy and Digital technologies. From 22 to 25 October these Hot Topics will be in focus.

Integration of the latest technology of a PNM in an existing Lamination Line

The LiSEC subsidiary in Australia has experienced remarkable growth, a testament to its commitment to excellence and innovation.

Tailoring a unique spacer application approach for world-class insulating glass

The partnership between Kong Weng Glass from Malaysia and LiSEC has existed for many years and is characterized by mutual trust, good communication and openness to each other's needs.

The partnership with Forel has facilitated Press Glass' specialization in structural and architectural glass production, catering to commercial and design sectors.

FGIA hosted a roundtable discussion called "Embracing Innovation in the Windows Industry” during the 2024 FGIA Annual Conference.

The Start-Up Zone at glasstec offers up-and-coming, innovative companies a platform to present themselves. BISS.ID GmbH will also be there in 2024.

A 30-year partnership in elevating glass processing efficiency

Representing Forel at Gulf Glass 2023 was Sergio Cosano, Forel’s Export Area Manager, who also had the opportunity to participate in the COP28 World Meeting.

From 20-22 February 2024, digitalBAU—the trade fair for digital solutions in the construction industry—will take place in Cologne for the third time.

In collaboration with the MakerSpace[A] in Amstetten, three glass processing technicians from LiSEC were able to use in real life what they learned so far.

The 2023 edition of Glasstech Asia was a resounding success, hosting over 200 companies and renowned brands in the glass industry.

On November 3, 2023, the new Engineering Center was opened at the LiSEC site in Seitenstetten.

Do you have large production of glass to process? The solution is a custom CMS system!

Forel invites you to visit its live demonstrations at Booth #1945

LiSEC will be showcasing its cutting-edge glass processing technologies and state-of-the-art machinery at booth #2831.

![F.l.t.r.: Lukas Schuller, Severin Gassner, Florian Buchberger, Andreas Mader and Günther Sterlike © MakerSpace[A] F.l.t.r.: Lukas Schuller, Severin Gassner, Florian Buchberger, Andreas Mader and Günther Sterlike © MakerSpace[A]](/sites/default/files/styles/6/public/news/2023/the-young-up-and-comers-of-lisec.jpg?itok=UEY-_WJ4)