Others also read

2020 - Looking back on what we have gone through together

Mr. Johann Stöger talks about the history of GLASTRONiC, corporate processes, sales markets, his goals, and much more.

The LAM 500 series is aimed at companies that need maximum productivity and automation. Designed to work integrated in a laminated cutting line or as part of a mixed line.

PlusLam is the cost-effective laminated glass line with advanced machines and sophisticated lamination technology.

The upgrades will be delivered and installed in March 2021.

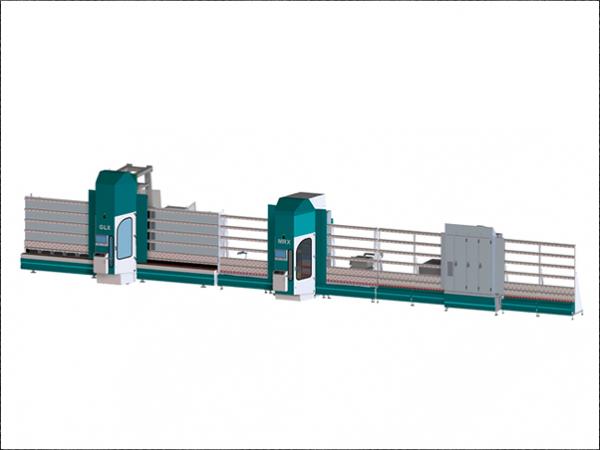

The MRX fully automatic milling and drilling machine delivers convincingly good performance and is easy to operate.

Glaston Corporation will publish its January−December 2020 Financial Statements Bulletin on Tuesday, 9 February, 2021 at around 13.00 p.m. Finnish time.

What does SplitFin stand for? How many operators do you need to run the SplitFin? Can laminated glass also be processed on the SplitFin?

New laser separation technology now offers the potential to significantly shorten the processing cycle and improve edge quality.

Glaston Group has closed a deal for a FC Series™ tempering line with one of the largest suppliers of turn key sunrooms in North America.

FIT Show has teamed up with Business Pilot, the cloud-based ERP / CRM system for fitting and installation companies, to develop a series of guides to help installers increase profitability.

High performance CNC machines and unique integrated lines for glass processing.

HEGLA’s PVC racking and storage system is a versatile product that can provide solutions for manufacturers struggling with a lack of space on the production floor.

In this video Marco Peric at Glas Gasperlmair in Austria is sharing his & his team's experiences on working with Glaston ProL glass laminating lines.

Glaston has closed a follow-up deal with Lippert Components Inc. for an automotive pre-processing line and an insulating glass line.

combiFIN is a compact but simultaneously highly efficient vertical processing line for flat glass with a thickness of typically 4 to 12mm.

Glaston has appointed Susanna Kohisevankoski as SVP People and Culture and a member of the Executive Management Group.

Glass Futures opens a virtual door to it Global Centre of Excellence - be part of our open design sessions.

A MappiSUPERTEMPER™ tempering furnace achieves the characteristics necessary to certify E30 glass for fire resistance.

Please join Viprotron in welcoming their newest team member: Scott Knisely.

Better quality, less costs and higher output – these are the benefits of the VSL-A.

FIT Show organisers have announced new dates for its 2021 event, postponing the fenestration industry’s flagship UK event from May until September 2021.

Managing Director of MKD32 Matthew Demmon has become the new president of British Glass after a unanimous vote at the company’s Annual General Meeting.

The “High Tech” IG line have evolved from the best of Forel’s latest equipment, mainly dedicated to the production of double, triple and even quadruple insulating glass units for both residential and commercial architecture.

Due to growing demand especially for heat treatment equipment Glaston’s order intake for the fourth quarter of this year will exceed the level in the fourth quarter of 2019.