Others also read

Experience the first ever virtual LiSEC Campus!

Guidelines for Viewing and Measuring Color of Decorative Glazing Products

In this sleek building, acid-etched glass at Volvo’s new dealership optimizes natural daylight to create a welcoming, well-designed space.

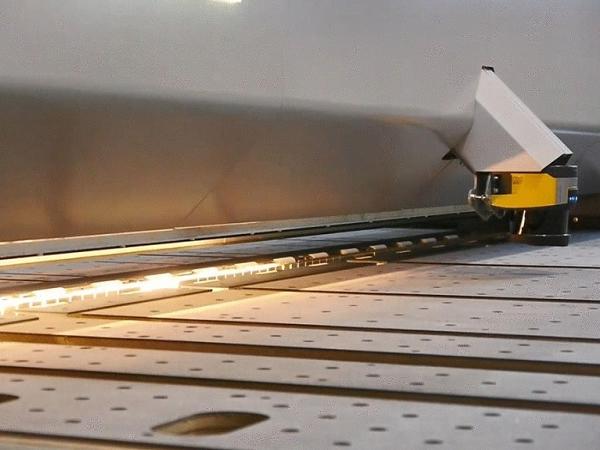

With a long-established history in glass machinery manufacturing, HEGLA has developed a fully automated, in-line, blade trimming system that provides greater accuracy and speed.

The newest line engraves precious metals, as gold, on the glass surface through the use of the most sophisticated serigraphy technology in both flat and curved glass.

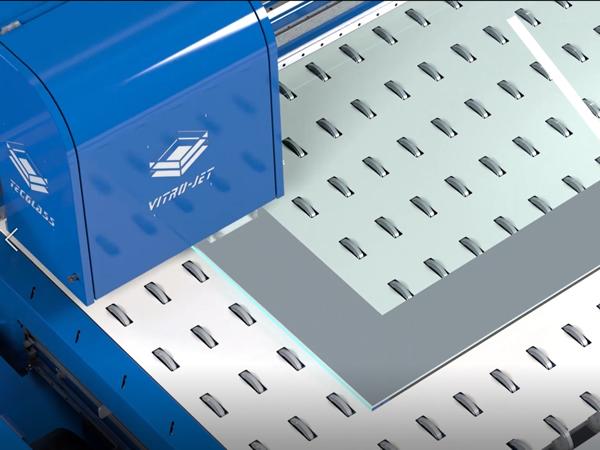

Today we are happy to announce a new partnership between Transparent Design S.R.L and Tecglass S.L for the supply of a digital printing line in extra-size.

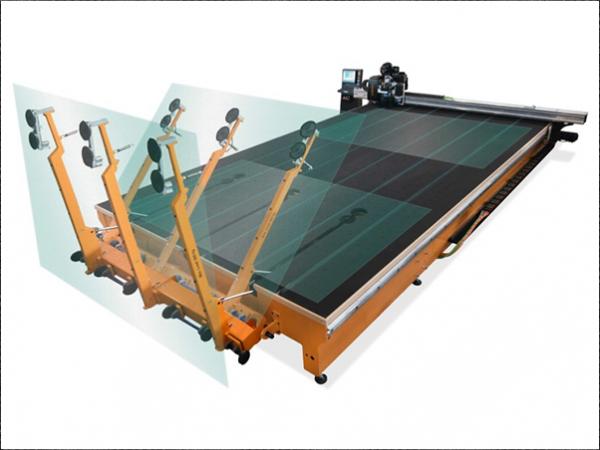

The StreamLam is a new, holistic cutting system for laminated glass.

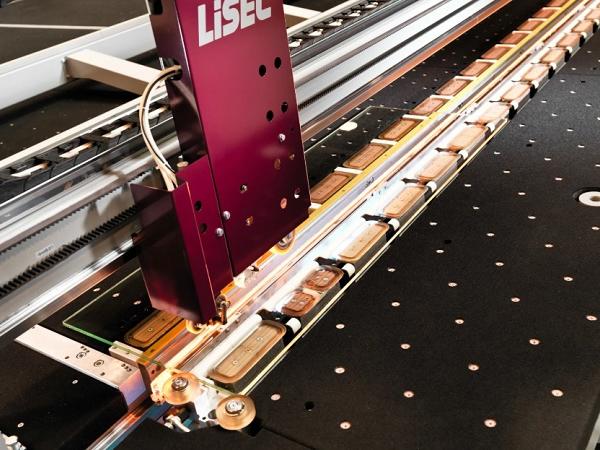

Localised stresses in laminated glass can cause faulty breakages during cutting. The modern suction cup mechanism from LiSEC helps to reduce the numbers of losses.

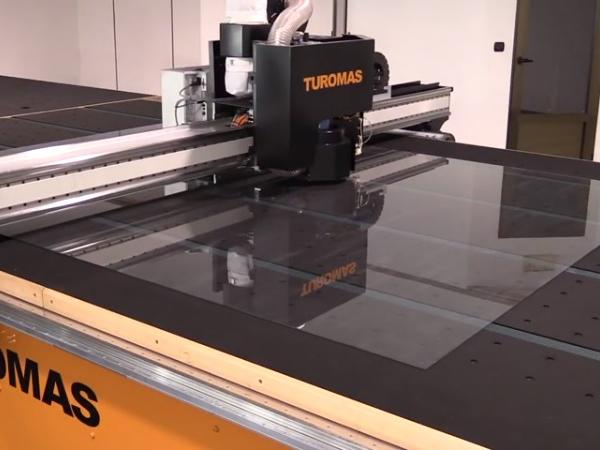

The TUROMAS loading system offers multiple benefits for glass processing companies, including productivity increase, optimization of plant layout, economic savings or factory safety.

When enhanced with Fenzi products, glass plays an increasingly crucial role in the world of packaging.

A new concept in digital printing, engineered by Tecglass to be a real, true ‘game changer’, designed to allow architecture professionals to take the leap into the world of digital printing.

Since the beginning of the 1990s, LiSEC has been actively shaping the cutting possibilities of laminated glass.

The RUBI 500 SERIES is aimed at companies that need maximum productivity, automation, efficiency and precision.

With the vast array of Tecglass ceramic ink colors the creative possibilities are endless.

Unlimited creativity: the printed glass can be processed further into insulating and safety glass, and can even be curved.

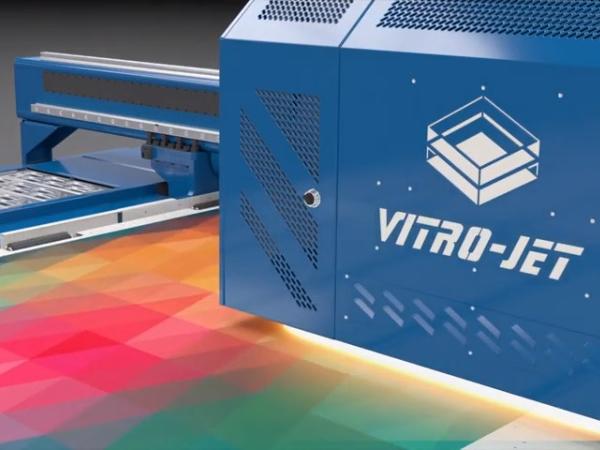

TECGLASS and ERDEM DIS TICARET A.S. Dis seal a new partnership deal with a breathtaking project for a Vitro-Jet FS24 digital printing extra-line.

Eastman Machine Company announces that it has appointed Technical Cutting (TeCS) of Nottinghamshire to represent its line of automated cutting systems in the UK and Ireland.

Tecglass breaks every record and expands its print resolution on glass to up to 2880 dpi, with 9 different ink drop sizes

Supertuff and LiSEC have been working together for 20 years now.

Addressing the challenges of prepreg processing, including cutting, requires an understanding of what makes them different from other composite materials.

Cutting 0.030 inch thick (0.76mm) EVA laminated glass with automated Eastman C125 conveyor system.

The cooperation between Glass Systems and LiSEC started when the new production facility in Swansea was opened.