Date: 10 October 2014

The new production line speed’line can manufacture triple-insulating units in the time it takes other lines to produce double-insulating glass. Like other Bystronic machines, speed’line is fully automated with solutions provided by Siemens.

.jpg)

Bystronic glass is famed for its pioneering machines, systems and services for the processing of architectural and automotive glass. Headquartered in Neuhausen-Hamberg in the south of Germany, the brand’s companies are active across the globe. In 1994, Bystronic glass became part of Conzzeta AG, a renowned Swiss industrial holding company. (Photo: istock: DeSnurb)

Drive technology from a single source

“Manufacturing triple-insulating glass in quick cycle times depends on three individual stages: applying the spacers, filling the cavity between the glass panes with gas, and sealing the units,” explains Jürgen Schnorr, Head of Electro-Mechanical Design at Bystronic glass. Each production step is handled by specialized machines, which are controlled by the Simotion Motion Control System. All drive components, including Sinamics converters and Simotics servomotors, are fully coordinated – in line with Siemens’ Integrated Drive System concept (IDS). Higher up the control hierarchy, the Simatic automation system is used to control the entire production line.

.jpg)

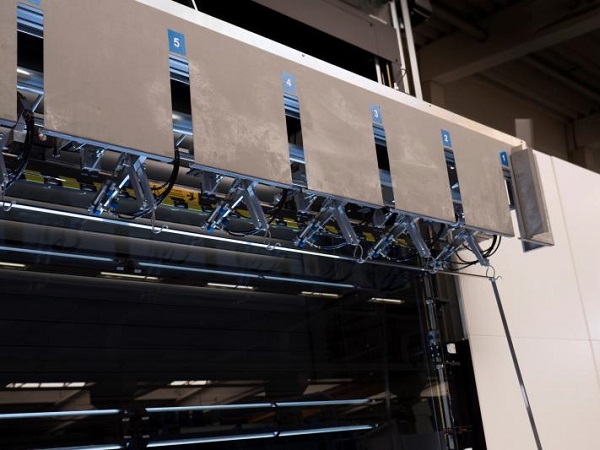

The new speed’line production facilities from Bystronic glass are designed for quick production of triple-insulating glass. (Photo: Bystronic glass)

Automated application

With speed’line, the application of the TPS (thermo plastic spacer) is completely automated. Two machines arranged one after the other position the spacer almost simultaneously on glass plates two and three. The advantage of TPS is that no separate pre-production stage is required; the spacer is instead applied in one strand directly to the glass pane in a patented process at a temperature of approximately 120 degrees Celsius. This method allows built-to-order production without loss of cycle time. The manufacturers do not have to divide the orders into standard and special formats, or subsequently sort the units. Thanks to Simotion control, the machines operate at maximum throughput. Plus, with the top-loading application provided by the Simotion Handling Toolbox, even complex window shapes can be manufactured with ease. G-code, the programming language commonly used for CAD applications, can be run directly.

Add new comment