Date: 25 August 2009

With its molybdenum monolithic rotary sputtering targets, PLANSEE fulfills these requirements and sets new standards for efficient coating. The targets will be presented in September at the Photovoltaic Solar Energy Conference in Hamburg/Germany.

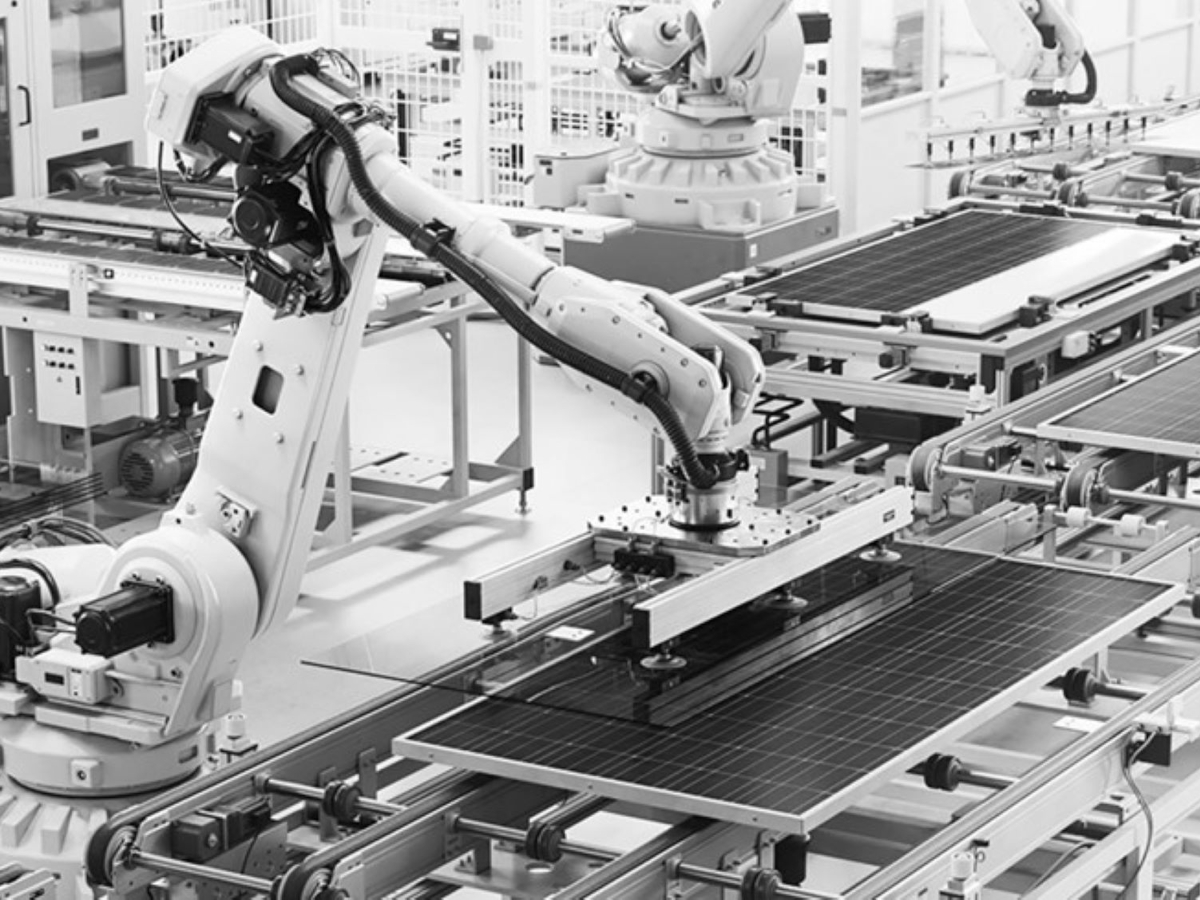

As the leading supplier of planar and rotary sputtering targets for thin-film solar cells and flat panel displays, PLANSEE is continually developing innovative solutions for optimal sputtering results and an efficient coating process. For the photovoltaic industry the company now offers monolithic rotary targets made of 100 % molybdenum. Their design without a backing tube pays off: hundreds of tests have already proven the benefits in practice.

Fast process. High power. Maximum yield.

Without a low-melting bonding layer, monolithic targets allow the highest heat transfer rates. Monolithic rotary targets can be run with up to 30 kW/ m power. The advantage: greater productivity and improved efficiency for a faster coating process.

In general, rotary targets have double or even triple the material utilization of planar targets. The rotary monolithic versions hold the record: they maintain their stability even after target utilization of more than 75 %. Producers thereby profit from bigger production runs.

The manufacturing of monolithic targets is carried out without any bonding. This lean process implies a fast production and maximum cost efficiency for customers.

Fully densified materials for maximum solar cell efficiency

In cooperation with all major solar cell manufacturers, PLANSEE has developed new materials that improve the performance of the thin film absorber layers. By alloying and developing material compounds, PLANSEE adapts inherent material properties to meet the specific requirements of the customers and tune the chemical composition of thin film absorbers. For the solar industry, the company offers materials such as Mo, Cr, MoNa, CuGa, CuIn or CuInGa.

With its complete in-house manufacturing, extensive expertise in powder metallurgy and cutting-edge deformation technologies, PLANSEE guarantees the best quality materials for the coating industry. They stand out for their full density, high purity and a uniform and fine grained microstructure. For its molybdenum targets the company delivers an actual chemical analysis for 21 elements confirmed in a 3.1 certificate.

The company will present its latest developments for the solar industry at the 24th European Photovoltaic Solar Energy Conference & Exhibition in Hamburg (Sept. 21-25 2009).

Add new comment