Date: 18 February 2015

Designated the Schueco AF 250, this advanced machine is able to increase throughput of windows and doors by reducing fabrication time and enhance the quality of individual components, thanks to the precision and repeatability inherent in computer-controlled machining.For example, for doors the Schueco AF 250 can perform the functions of four different fabricating machines – a copy router, an end-milling machine, a door-hinge drilling machine and a punch – leading to savings in both capital requirements and factory space and optimising overall efficiency.

The Schueco AF 250 is simple to operate using modern control software and connects to Schueco’s advanced SchuCal programming software. Its versatility in use, laser-measured x-axis and automatic 3-sided machining without an angled head, enable it to set new standards in its price class.

Measuring 5280 mm (L), 1640 mm (W) and 1990 mm (H) and weighing approx 2200 kg, the Schueco AF 250 is air-cooled with 3.8 kW spindle running at a maximum speed of 18,00 rpm. Its inherently strong, electro-welded steel machine bed can support heavy loads, while its absolute axis position-measuring system saves machining time by obviating the need for a reference run.

Two collapsible fixed stops accurately define the zero point enabling profile lengths up to 6 m to be processed.

Accessories available include a profile length measuring system, a second tool changer magazine with 3 spaces (in addition to the 5-space automatic tool changer provided as standard) and a ceiling kit consisting of a polycarbonate roof panel with fluorescent lighting.

The AF 250 CNC machine is part of Schueco’s philosophy to provide its fabricator partners with a wide range of advanced machinery to enable them to achieve the highest levels of productivity and consistent quality.

For further information and full technical details of the Schueco AF 250 CNC machine or any other item in the Schueco machinery range, please email mkinfobox@schueco.com.

ENDS

Issued on behalf of Schueco UK Limited by Acumen Marketing Communications Ltd, Watermill House, Chevening Road, Chipstead, Sevenoaks, Kent TN13 2RY. Further press information from John Mounsey/Lester Corney, tel: 01732 456444; e-mail: lester.corney@acumen-communications.com

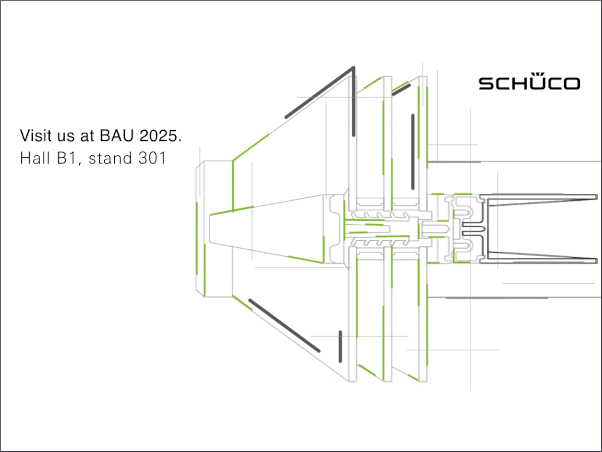

Schüco – System solutions for windows, doors, façades and solar products. Together with its worldwide network of partners, architects, specifiers and investors, Schüco creates sustainable building envelopes which focus on people and their needs in harmony with nature and technology. The highest demands for design, comfort and security can be met, whilst simultaneously reducing CO2 emissions through energy efficiency, thereby conserving natural resources. The company and its Metal and PVC-U divisions deliver tailored products for newbuilds and renovations, designed to meet individual user needs in all climate zones. With 4800 employees and 12,000 partner companies, Schüco is active in 78 countries and achieved a turnover of 1.5 billion euros in 2013. For more information, visit www.schueco.co.uk

Add new comment