Date: 19 August 2019

After REHAU won over its first door manufacturer for the use of the zero-joint technology at the beginning of the year, the company DRE, a Polish manufacturer of interior doors, is now using the high-quality processing method as a further manufacturer. To up the spec of their doors DRE have also switched to using polymer surfaces from the REHAU collection, taking interior door design to the next level.

Doors made to measure

High-gloss or matt surfaces have long been regarded as state-of-the-art in the kitchen sector. Lacquer surfaces are, however, very sensitive, which has led to the use of modern, robust, UV-resistant polymer laminates that are less susceptible to scratches. Wanting to embrace these features for their own products, Polish interior door manufacturer DRE is now making the most of REHAU’s vast collection of polymer surfaces. Doors always require bespoke solutions, often needing to be adapted to the building’s architecture and structural conditions and that’s why polymer surfaces are the ideal material. Using conventional woodworking tools, cuts for sheets and frames can be individually adapted to the exact door openings – perfect for joiners and industrial production alike. The RAUVISIO brilliant colour palette currently offers eight colours available in both high-gloss and matt finishes

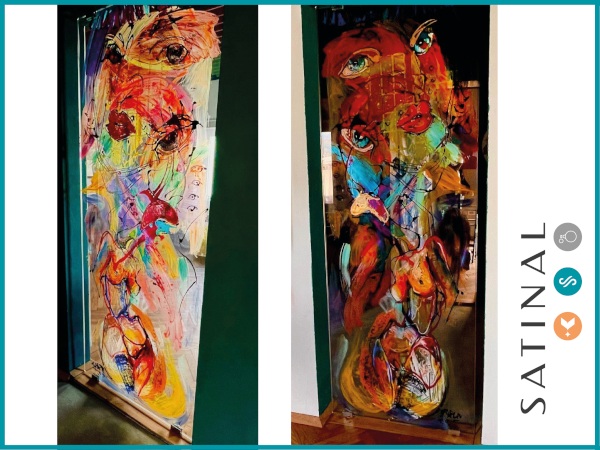

New design level: Doors integrate harmoniously into the overall interior.

With RAUVISIO brilliant, the entire interior design can be raised to a new design level. Whether it be for the kitchen, bathroom or retail spaces, RAUVISIO brilliant lets you create the perfect design match, with the possibility to have both interior doors and front panels made from exactly the same material. This is perfect for plain colours, especially as not all whites and greys are the same.

A premium solution – even for door rebates

Until recently, it was customary for doors to use melamine- or paper-based edgebands with bonding as these better met the special requirements of door rebates. Zero-joint technology, however, takes door rebate edging to a whole new level. Extremely high adhesion makes the door component highly resistant to splinters, increasing its service life and overall quality. REHAU edgebands now give DRE the chance to refine their doors without rebates, allowing for a seamless closure between surface and edge without a visible joint. The door becomes a single component as though from a single cast, with the further addition of locking technology, giving doors by DRE a unique selling point in Poland.

600450

600450

Add new comment