Date: 17 December 2012

Naturally this requires high availability and no unexpected breakdowns of systems and stand-alone equipment. But how can companies ensure this during production? Who assists in preventive maintenance? Who can help when a system or machine happens to fail?

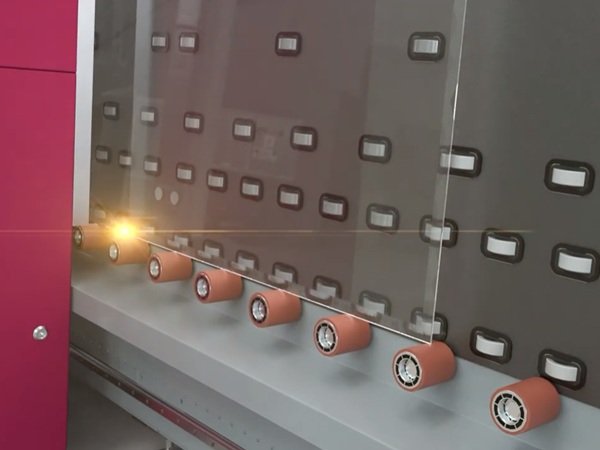

LiSEC considers itself co-responsible for its customers' success. Famous for high-quality products with a long lifetime, LiSEC has recently developed GPS.asset, a tool to maintain and continuously improve operational availability.

On the one hand, GPS.asset offers direct access to specific machine information, with support for malfunctions through GPS.maintain. On the other hand, and at a superior level, GPS.assetcheck provides an overview of service and maintenance tasks required for all machines and systems, and helps plan maintenance activities.

GPS.maintain: High availability through direct support to the machine

An essential factor for high machine availability is preventive maintenance. Any parts that are crucial for the production process have a specific maintenance interval. A meter will record the hours of operation, the number of units processed as well as other data, and determine the next maintenance date. Based on this, the system will display alert messages and forward these to the central GPS.assetcheck tool. In addition, the state of extremely crucial machine parts is checked on a regular basis. If the system finds that their condition has deteriorated, it will automatically forward an alert. If a machine fails in spite of these preventive measures, the software will enable quick troubleshooting by providing detailed documentation (e.g. service manual, e-documentation), and by offering the possibility to archive the experiences made in troubleshooting for future use.

GPS.assetcheck: Providing an overview and identifying weak points

A daily overview of the state of the entire machinery is of great importance to the production manager and the person in charge of maintenance. An 'intuitive cockpit' can display this, as well as all relevant production data on glass units manufactured and process parameters. GPS.assetcheck collects and saves information on all the machinery, which allows you to analyse downtimes and failures within an individually set time range. Furthermore, it forwards service information to the central system, allowing you to make maintenance plans based on current needs. So far, use has shown that GPS.assetcheck not only reveals potential improvements regarding machines and maintenance processes but also identifies room for improvement in organising production.

Add new comment